Keywords“Flotation frothers”Related articles

Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

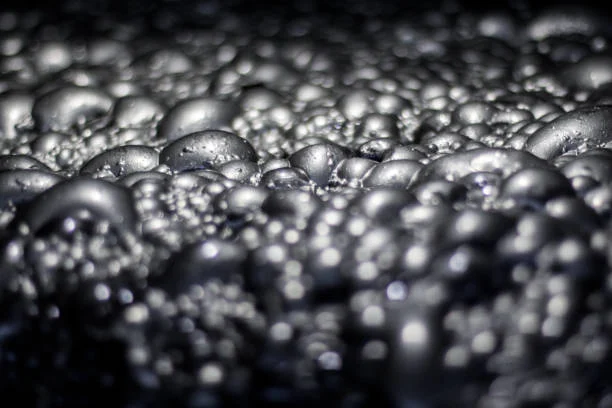

Choose United Chemical for premium 98% purity sodium cyanide. As a r...Understanding Flotation Frothers

The choice of frother, whether it be traditional options like pine o...NaCN UC-98%+ Sodium Cyanide by United Chemical

After over 1000 days and nights of relentless research, spanning fiv...Methods and Processes for Removing Cyanide on the Surface of Sulfide Ores

Sulfide ores often retain cyanide on their surface post - processing...Research on the Inhibition Mechanism of Sodium Cyanide in Lead-Zinc Separation Flotation

Lead-zinc separation flotation is crucial in mineral processing, and...Reducing Sodium Cyanide Consumption in Gold Concentrate Leaching

Gold concentrate cyanidation relies on sodium cyanide, but high usag...Production Practice of Treating Sodium Cyanide Wastewater with Hydrogen Peroxide

Production practice of treating sodium cyanide wastewater with hydro...The Role of Sodium Cyanide in Mineral Processing Chemicals

Sodium cyanide plays many roles in mineral processing chemicals. Lea...The Role of Sodium Sulfide in Mineral Processing

Sodium sulfide is a versatile reagent in mineral processing, crucial...Discussion on the Technology of Extracting Gold with Sodium Cyanide

Details on the use of sodium cyanide in gold extraction. Explore the...Enhancing Cyanidation for Gold Extraction from Refractory Ores

Recent advances in enhanced cyanidation for gold extraction from ref...The Interactions of Sodium Sulfide with Other Reagents in the Flotation Process

The complex interaction of sodium sulfide with collectors, frothers ...