Introduction to Gold Ore Dressing Processes

Gold ore dressing processes are designed to extract gold elements from ores. Common methods include gravity separation, flotation, and cyanidation. Among them, gravity separation is widely used in gold ore dressing due to its simplicity, low cost, and environmental friendliness. This article will focus on the process flow and advantages of re - processing tailings from gravity - separated gold mines.

The Necessity of Reprocessing Tailings from Gravity - Separated Gold Mines

In the gold ore dressing process, tailings are inevitable by - products. These tailings still contain a certain amount of gold. If left untreated, it will lead to resource waste and environmental pollution. Reprocessing tailings through gravity separation can not only increase the gold recovery rate but also reduce the environmental impact of tailings, achieving efficient resource utilization.

Process Flow of Reprocessing Tailings from Gravity - Separated Gold Mines

1.Tailings Pretreatment

Tailings pretreatment is the first step in the gravity separation process. Its purpose is to remove impurities in the tailings to improve the effect of subsequent gravity separation. Common pretreatment methods include screening, desliming, and thickening.

2.Gravity Separation Process

The gravity separation process is the core step of tailings re - processing. Depending on the particle size and mineral composition of the tailings, different gravity separation equipment and methods can be selected. Common gravity separation equipment includes shaking tables, jigs, and spiral chutes. Shaking tables are suitable for fine - grained tailings, while jigs are suitable for coarser - grained tailings.

3.Further Tailings Treatment

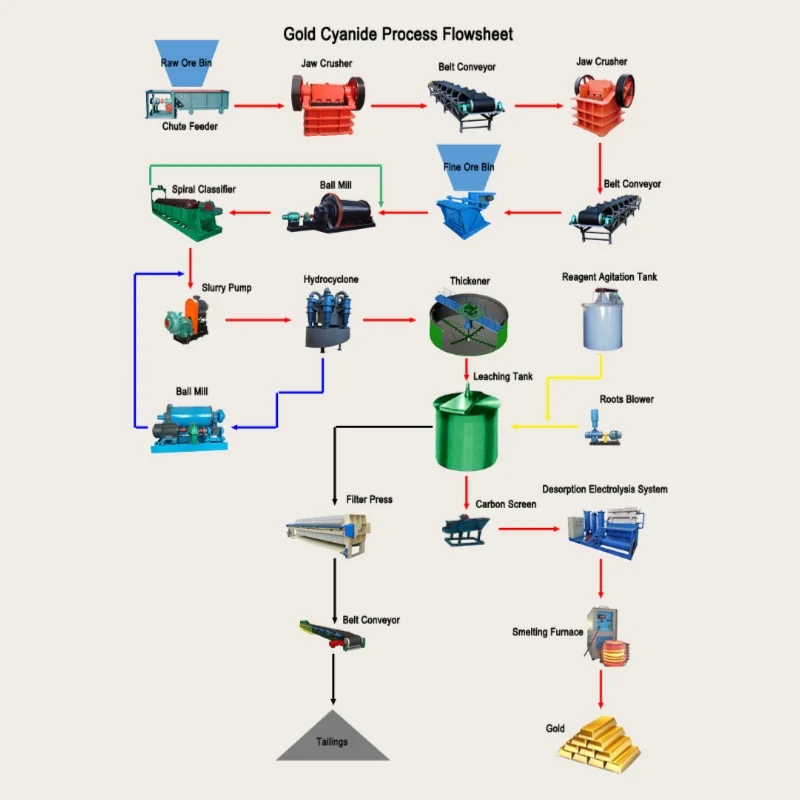

After the gravity separation process, the gold elements in the tailings are effectively recovered, but some tailings still need further treatment. Cyanidation can be used to re - process the tailings after gravity separation to increase the gold recovery rate.

Advantages of Reprocessing Tailings from Gravity - Separated Gold Mines

1.Improved Resource Utilization

By re - processing tailings through gravity separation, the gold elements in the tailings can be effectively recovered, improving resource utilization and reducing resource waste.

2.Reduced Environmental Pollution

Tailings contain a large number of harmful substances. If not treated, they will cause serious pollution to the environment. By re - processing tailings through gravity separation, the amount of tailings discharged can be reduced, reducing environmental pollution.

3.Significant Economic Benefits

The gravity separation process has a low cost and is easy to operate. By re - processing tailings, additional economic benefits can be obtained, improving the economic efficiency of mining enterprises.

In conclusion, re - processing tailings from gravity - separated gold mines is an efficient and environmentally friendly ore dressing process. It can effectively improve resource utilization, reduce environmental pollution, and has significant economic benefits. United Chemical, with its rich experience and technical advantages, provides high - quality leaching agents and ore dressing solutions for customers, helping mining enterprises achieve sustainable development.

- Random Content

- Hot content

- Hot review content

- Industrial concentrated nitric acid 55%-68%

- Sodium Isobutyl Xanthate SIBX 90%

- Anhydrous Ammonia 99% Liquid

- Lithium chloride, 99.0%,99.5%

- 97% 2-Hydroxypropyl methacrylate

- Calcium Chloride 74% Flakes

- Fuel Additive Octane Value Booster Ferrocene

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Sodium Cyanide (CAS: 143-33-9) End user certificate (Chinese and English version)

- 7Anhydrous Oxalic acid 99.6% Industrial Grade

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: