Keywords“Electrolysis refining”Related articles

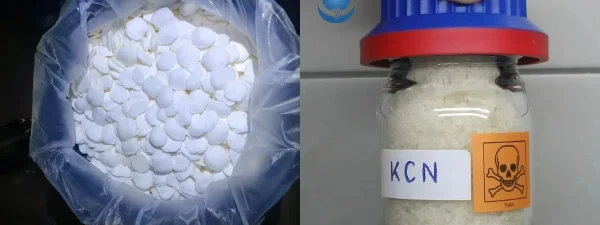

Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

Choose United Chemical for premium 98% purity sodium cyanide. As a r...Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

Sulfuric acid, with the chemical formula H₂SO₄, is a potent mineral ...Sodium Cyanide Electroplating Zinc Process: A Comprehensive Analysis

Sodium cyanide electroplating zinc is a vital process in metal surfa...Strategies to Reduce Sodium Cyanide Usage While Maintaining Recovery Rates

Mining and metal extraction rely on sodium cyanide for precious meta...Electrolytic Oxidation Process for Treating Sodium Cyanide Wastewater

Electrolytic oxidation is a promising method for treating highly tox...Experimental Study on Treatment Methods of Cyanide-Poor Liquid in a Gold Mine

Experimental study on the treatment of low-cyanide liquids in gold m...Research on Cyanide-Containing Wastewater Treatment and Comprehensive Recovery of Valuable Elements

The latest research results on cyanide wastewater treatment and comp...Pollution Control of Sodium Cyanide in the Gold Refining Process

Sodium cyanide is widely used in gold refining but brings severe env...The Pivotal Role of Sodium Hydroxide in the Metallurgical Industry

Sodium hydroxide, or caustic soda, is indispensable in the metallurg...Chlorination Process for Treating Cyanide Gold Sludge

Chlorination Process for Treating Cyanide Gold Sludge offers a compr...The differences between the chemical raw materials sodium cyanide and potassium cyanide

Sodium cyanide and potassium cyanide are vital inorganic chemicals w...Controlling Reaction Conditions in Cyanide Wastewater Treatment

Precise control of pH, temperature, oxidant dosage, and ORP in cyani...