In the vast and complex realm of the metallurgical industry, sodium hydroxide (NaOH), commonly known as caustic soda or lye, plays a multifaceted and indispensable role. This strong alkaline compound, available in solid (such as flake or granular) and liquid forms, is a key player in various metallurgical processes, from the extraction of metals from their ores to the final finishing of metal products.

1. Ore Processing and Extraction

1.1 Conversion to Soluble Salts

One of the primary functions of sodium hydroxide in metallurgy is to convert the valuable components within ores into soluble salts. This is crucial as it enables the separation of the desired metal from the insoluble impurities present in the ore. For instance, in the extraction of tungsten, the process begins with roasting the tungsten - bearing ore, like scheelite or wolframite, with sodium hydroxide or sodium carbonate. This roasting process transforms the tungsten minerals into soluble sodium tungstate. The soluble sodium tungstate can then be further processed, separated from the insoluble residue, and eventually converted back into pure tungsten through subsequent chemical reactions.

1.2 Leaching Processes

Sodium hydroxide is also used in leaching processes. For certain metal ores, leaching with sodium hydroxide solutions can selectively dissolve the metal values. This is especially relevant for low - grade or complex ores where traditional smelting methods may not be cost - effective. In the extraction of aluminum from bauxite ore via the Bayer process, sodium hydroxide is used to leach out alumina. Bauxite contains impurities such as iron oxides, silica, and titanium dioxide. When bauxite is treated with hot, concentrated sodium hydroxide solution, the alumina reacts to form soluble sodium aluminate, while most of the impurities remain insoluble and can be separated by filtration.

2. Metal Refining

2.1 Removal of Impurities

During metal refining, sodium hydroxide serves as a powerful agent for removing various impurities from metals. It can react with oxides, sulfides, and other non - metallic impurities present on the surface or within the metal matrix. In the refining of copper, for example, sodium hydroxide can be used to remove copper oxide impurities. When copper with oxide impurities is treated with sodium hydroxide, a redox reaction occurs. The hydroxide ions reduce the copper oxide to metallic copper, and at the same time, form soluble sodium salts with other non - metallic impurities, which can then be easily removed. This process helps to improve the purity and quality of the copper, enhancing its electrical conductivity and mechanical properties.

2.2 Electrolytic Refining Support

In electrolytic refining processes, sodium hydroxide can play a role in maintaining the stability of the electrolyte and facilitating the smooth deposition of pure metal at the cathode. For some metals, like zinc, in alkaline electroplating baths, sodium hydroxide is used as a complexing agent and a conductive salt. It complexes with zinc ions to form zincate ions, which helps to keep the plating bath stable and improves the bath's conductivity. This leads to a more uniform deposition of zinc on the cathode, resulting in a better - quality zinc coating.

3. Surface Treatment

3.1 Degreasing and Cleaning

Metal surfaces often have contaminants such as oils, greases, and organic residues that need to be removed before further processing. Sodium hydroxide is an effective degreasing agent. It reacts with the esters of fatty acids present in oils and greases through a process called saponification. For example, when stearic acid esters in vegetable oils react with sodium hydroxide, they produce water - soluble sodium stearate, commonly known as soap, and glycerol. This makes it possible to wash away the contaminants with water, leaving a clean metal surface. This cleaning process is essential for subsequent operations such as electroplating, painting, or welding, as a clean surface ensures better adhesion of coatings or stronger bonds.

3.2 Etching and Surface Preparation

Sodium hydroxide is also used in metal etching processes. For aluminum and its alloys, sodium hydroxide is widely used for alkali etching, often carried out before anodizing or other surface treatment processes. The etching with sodium hydroxide creates a uniform and clean surface texture on the aluminum alloy, increasing the surface area and improving the adhesion of subsequent coatings. The rate of etching can be controlled by adjusting the concentration of sodium hydroxide, the temperature, and the time of exposure.

4. Desulfurization in Steel and Other Metal Production

In the production of steel and some other metals, sulfur is an undesirable impurity as it can cause brittleness in steel, reducing its mechanical properties and weldability. Sodium hydroxide can be used as a desulfurizing agent. In the steel - making process, when sodium hydroxide is added to the molten metal, it reacts with sulfur to form sodium sulfide. The sodium sulfide formed is less soluble in the molten metal and can be removed through slagging operations. This helps to improve the quality of the steel and other metals by reducing the sulfur content to acceptable levels.

5. Role in Electrochemical Processes

5.1 Electrolysis of Aluminum

In the modern aluminum industry, the Hall - Héroult process, the primary method for producing aluminum, relies on an electrolyte system. Although the main electrolyte is a mixture of cryolite and alumina, sodium hydroxide can be present in small amounts in some variations of the process or in the pre - treatment stages. Sodium hydroxide can affect the electrical conductivity and the chemical reactions occurring at the electrodes. It helps to facilitate the flow of current through the electrolyte, which is crucial for the decomposition of alumina into aluminum and oxygen at the cathode and anode respectively.

5.2 Other Electrochemical Metal Deposition and Recovery

Sodium hydroxide is also used in some electrochemical processes for metal deposition and recovery. For example, in the electrodeposition of certain metals from their solutions, sodium hydroxide can be used to adjust the pH of the electrolyte solution. This pH adjustment can have a significant impact on the electrochemical reactions, influencing factors such as the rate of metal deposition, the quality of the deposited metal layer, and the selectivity of metal deposition when multiple metal ions are present in the solution.

In conclusion, sodium hydroxide is an essential chemical in the metallurgical industry. Its diverse applications in ore processing, metal refining, surface treatment, desulfurization, and electrochemical processes contribute significantly to the production of high - quality metals and metal products. As the metallurgical industry continues to evolve, the role of sodium hydroxide is likely to remain crucial, with ongoing research and development focused on optimizing its use and exploring new applications to improve efficiency and reduce environmental impact.

- Random Content

- Hot content

- Hot review content

- Ammonium Chloride 99.5% Mining Collector

- 99.5% min Ammonium Chloride For Industrial Use

- Sodium Persulfate,Sodium Persulphate,supplier 99.00%

- calcium chloride anhydrous for food

- Lithium hydroxide 99% Solid

- Calcium Chloride 74% Flakes

- Cobalt Sulfate 98% Brown yellow or red crystal

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

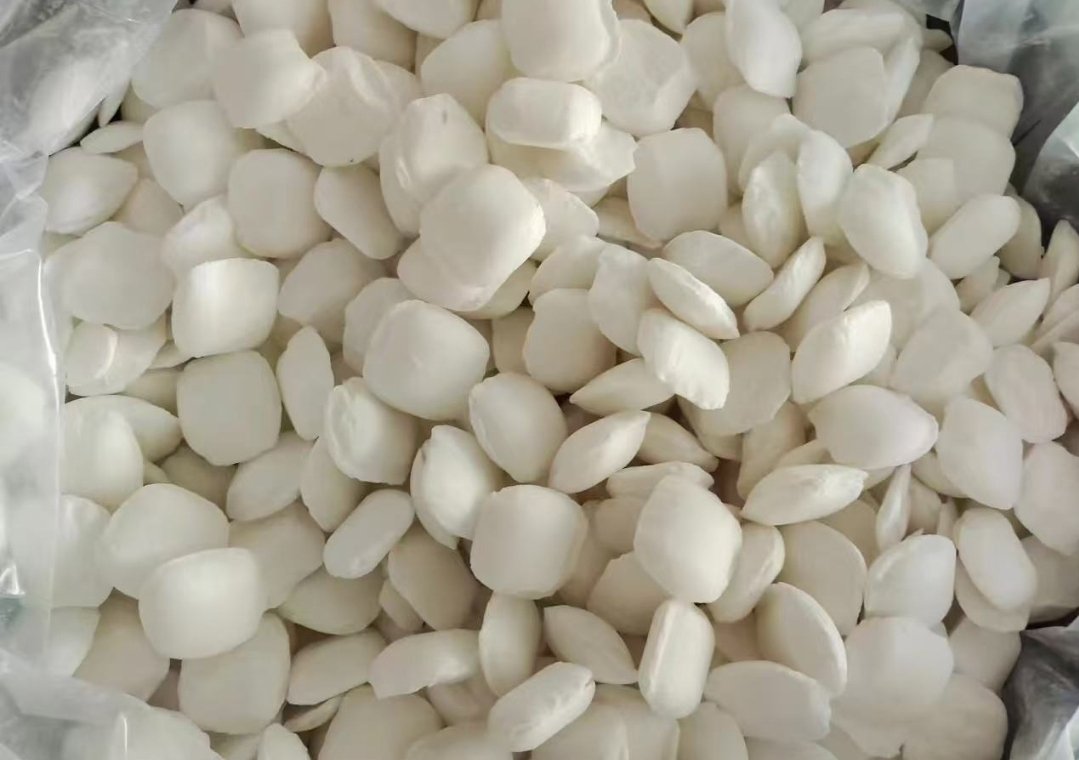

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: