Introduction

Gold refining is a complex process aimed at purifying gold from its ores or impure forms. Among the various techniques employed, the use of Sodium cyanide in the gold extraction and refining process has been prevalent for a long time. Sodium cyanide plays a crucial role in separating gold from its ore through a process called Cyanide leaching. However, the use of this highly toxic chemical poses significant environmental and health risks, making Pollution control an absolute necessity.

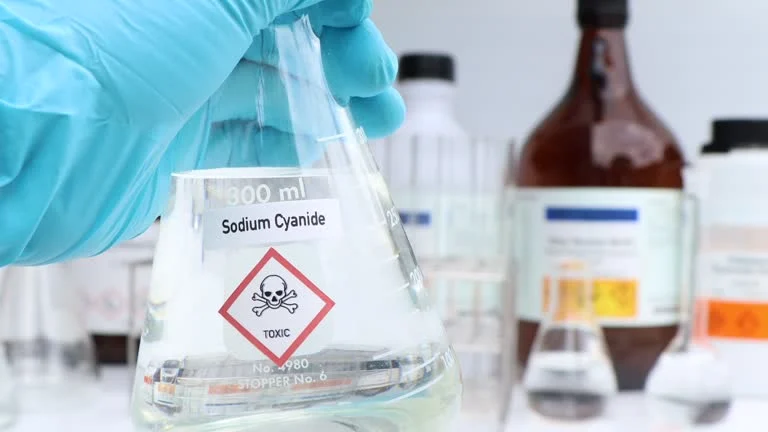

The Role of Sodium Cyanide in Gold Refining

Cyanide Leaching Process

Cyanide leaching is a common method in gold mining and refining. Sodium cyanide (NaCN) is used to dissolve gold from the ore. In the presence of oxygen, Sodium Cyanide reacts with gold to form soluble gold cyanide complexes. For example, in heap leaching, cyanide solutions are sprayed over heaps of crushed ore spread across large collection pads. The cyanide solution percolates through the ore heap, dissolving the gold, which is then collected in the solution. In tank leaching, which is carried out in more controlled environments like large tanks, the process is similar, but it generates tailings as a waste product.

Chemical Reactions Involved

In the cyanide leaching of gold, sodium cyanide, in combination with oxygen and water, reacts with gold in the ore. This chemical interaction results in the formation of a soluble compound that contains gold. This soluble gold compound can then be further processed through subsequent steps to recover pure gold.

Dangers of Sodium Cyanide Pollution

Environmental Impact

Cyanide pollution can have devastating effects on the environment. If cyanide solutions leak from containment systems such as holding tanks, ponds, or during transportation, they can contaminate soil, water bodies, and air. In water, cyanide can kill aquatic life, disrupting entire ecosystems. For instance, it can inhibit the respiratory systems of fish and other aquatic organisms, leading to their death. In soil, cyanide can affect plant growth and soil microbial activity, potentially rendering the land unsuitable for agriculture.

Health Risks to Humans

Sodium cyanide is extremely toxic to humans. Even small amounts can be lethal. Inhalation, ingestion, or skin contact with cyanide can cause acute poisoning. Cyanide inhibits the body's ability to use oxygen, leading to symptoms such as rapid breathing, dizziness, headache, and in severe cases, respiratory failure and death. Long - term exposure to low levels of cyanide can also have chronic health effects on the nervous system, thyroid gland, and other organs.

Pollution Control Measures

Engineering Controls

Containment Systems

Primary Containment: High - quality polyurea coatings are often used to line the inner surfaces of holding tanks, retention ponds, and storage basins where cyanide solutions are stored. Polyurea offers excellent chemical resistance, preventing the corrosive effects of cyanide on the containment materials. It also has a fast curing time, allowing for quick installation and reducing downtime in mining operations.

Secondary Containment: In addition to primary liners, secondary containment systems are essential. Polyurea coatings can be applied to floors, walls, and other surfaces around the primary containment areas. This creates a backup layer to catch any potential leaks or spills. Even if the primary containment fails due to unforeseen circumstances such as mechanical damage or corrosion, the secondary containment can prevent cyanide from escaping into the environment.

Leak Detection Systems

Installing advanced leak detection systems is crucial. These systems can continuously monitor the integrity of containment structures. For example, some systems use sensors to detect changes in pressure, flow, or chemical composition within the containment system. If a leak is detected, immediate action can be taken to prevent further contamination.

Process Optimization

Alternative Leaching Methods

Researchers are constantly exploring alternative methods to cyanide leaching to reduce the use of sodium cyanide. One such method is bioleaching, which uses microorganisms to extract gold from the ore. Some bacteria can oxidize the sulfur - bearing minerals in the ore, releasing the gold. This method is more environmentally friendly as it does not involve the use of toxic chemicals like cyanide. Another alternative is the use of thiosulfate leaching, which uses thiosulfate salts instead of cyanide to dissolve gold. Although thiosulfate leaching has its own challenges such as complex process control and lower gold recovery rates in some cases, it offers a potential solution to reduce cyanide - related pollution.

Improving Recovery Efficiency

Optimizing the gold recovery process can also help in pollution control. By improving the efficiency of gold extraction from the cyanide solutions, less cyanide - laden waste will be generated. Advanced filtration and separation techniques can be used to ensure that as much gold as possible is recovered from the cyanide solutions before the waste is disposed of. This reduces the amount of cyanide that needs to be treated in waste management processes.

Waste Management

Treatment of Cyanide - Containing Waste

Cyanide - containing waste, such as tailings from tank leaching, needs to be treated properly to reduce its toxicity. One common treatment method is the use of chemical oxidation. For example, adding hydrogen peroxide (\(H_2O_2\)) or chlorine - based oxidants to the cyanide - containing waste can convert the cyanide to less toxic compounds. Through this oxidation process, the highly toxic nature of cyanide is mitigated.

Safe Disposal of Treated Waste

After treatment, the waste needs to be disposed of in a safe manner. Tailings can be stored in specially designed tailings impoundments that are lined with materials to prevent leakage. These impoundments should be located in areas where there is minimal risk of contaminating water sources or other sensitive environmental areas. Regular monitoring of the impoundments is necessary to ensure that no leakage occurs over time.

Regulatory Compliance

Laws and Regulations Governing Cyanide Use

There are strict laws and regulations at local, national, and international levels that govern the use, storage, transportation, and disposal of sodium cyanide in the Gold refining industry. For example, in many countries, mining companies are required to obtain permits for using cyanide, which involve demonstrating that they have proper pollution control measures in place. They must also adhere to specific limits on the amount of cyanide that can be released into the environment.

Monitoring and Enforcement

Government agencies are responsible for monitoring the compliance of gold refining operations with these regulations. Regular inspections of mining sites, laboratories, and waste management facilities are carried out to ensure that companies are following the proper procedures for handling sodium cyanide. In case of non - compliance, penalties can be imposed, which may include fines, suspension of operations, or revocation of permits.

Conclusion

The use of sodium cyanide in gold refining is a double - edged sword. While it is an effective method for gold extraction, the associated pollution risks are significant. However, through a combination of engineering controls, process optimization, proper waste management, and strict regulatory compliance, it is possible to minimize the negative impacts of sodium cyanide pollution in the gold refining process. Continued research and development of alternative technologies and improved pollution control measures are essential to ensure the sustainable development of the gold refining industry while protecting the environment and human health.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- Flexible Customer and Supplier Relations Specialist (: Indonesia)

- Ammonium Chloride 99.5% Mining Collector

- Sodium bisulfite 99% High Quality Factory Supply

- Potassium Permanganate – Industrial Grade

- Cyanoacetic acid 99% Powder

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 6Oxalic acid for mining 99.6%

- 7Calcium hydroxide Industrial Grade 90%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: