Sodium cyanide (NaCN) and potassium cyanide (KCN) are both crucial inorganic chemical raw materials with significant industrial applications. However, they possess distinct characteristics that set them apart in various aspects. Let's explore their differences in detail across multiple dimensions.

Physical Properties

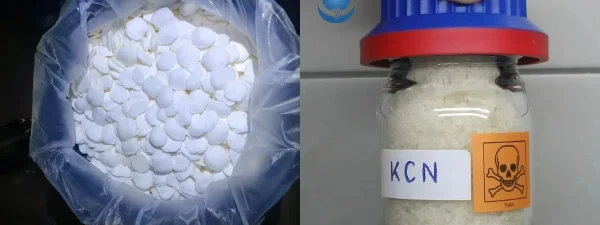

Appearance

Potassium cyanide typically presents as white spherical hard lumps, while sodium cyanide is seen in the form of white crystalline granules or powder. Additionally, potassium cyanide emits a faint bitter almond odor, which can be a subtle yet important identifying feature. Sodium cyanide, on the other hand, is highly hygroscopic and exhibits corrosive properties, making it necessary to store and handle with extreme caution to prevent moisture absorption and potential damage to storage containers.

Melting Point

Regarding melting points, potassium cyanide has a relatively high melting point of approximately 634.5°C, while Sodium Cyanide melts at around 563.7°C. This difference in melting points can influence their processing and usage in industrial settings where temperature control is critical.

Solubility

In terms of solubility, potassium cyanide readily dissolves in water and glycerol, facilitating its use in various aqueous-based processes. Sodium cyanide, conversely, demonstrates solubility in liquid ammonia and ethanol, enabling its application in specific chemical reactions and manufacturing processes that require these solvents.

Density

The densities of these two compounds also vary, with potassium cyanide having a density of 1.52 g/cm³ and Sodium cyanide being denser at approximately 1.60 g/cm³. These density differences can impact handling, transportation, and mixing processes in industrial applications.

Chemical Properties

Reactivity with Other Substances

When it comes to chemical reactivity, potassium cyanide reacts with acids to produce highly toxic hydrogen cyanide gas, a reaction that must be carefully controlled to prevent the release of this deadly substance. Sodium cyanide, upon exposure to carbon dioxide, undergoes slow decomposition, a characteristic that affects its storage and stability over time. Potassium cyanide releases heat when reacting with water, which can pose risks if not properly managed. Sodium cyanide, when mixed with strong oxidizers, may lead to explosive reactions, emphasizing the importance of strict handling protocols.

Applications

Industrial Uses

The applications of potassium cyanide and sodium cyanide diverge significantly. Potassium cyanide finds extensive use in the electroplating industry, where it plays a vital role in enhancing the quality and durability of metal coatings. It also serves as an intermediate in organic synthesis, contributing to the production of various organic compounds. Additionally, potassium cyanide is involved in the preparation of ferricyanides, which have applications in photography and other chemical processes.

Sodium cyanide, on the other hand, is predominantly utilized in the extraction of precious metals such as gold. Its ability to form stable complexes with gold ions makes it an essential reagent in gold mining and refining operations. It is also employed in the production of nitriles, which are important building blocks in the synthesis of numerous chemicals, plastics, and pharmaceuticals. Furthermore, sodium cyanide has applications in the pharmaceutical industry, although its use is highly regulated due to its extreme toxicity.

Safety Considerations

Handling and Storage

Safety is of utmost importance when dealing with both potassium cyanide and sodium cyanide due to their extreme toxicity. Potassium cyanide is typically packaged in sealed steel drums to prevent leakage and exposure. It must be transported in strict compliance with hazardous chemical regulations, and its production requires stringent safety measures to protect workers from exposure. In the event of skin contact with potassium cyanide, immediate medical attention is required as it can rapidly lead to poisoning. Ingestion of even a small amount can be fatal.

Sodium cyanide should be stored in a cool, dry place to prevent moisture absorption and degradation. During handling, precautions must be taken to prevent container damage, as any leakage can lead to environmental contamination and pose significant risks to human health. In case of a sodium cyanide leak, there are standardized emergency response procedures to follow to minimize the impact on the environment and human safety. Inhalation of sodium cyanide can cause severe damage to the respiratory system, and it also poses a significant environmental pollution risk if not properly managed.

In conclusion, while potassium cyanide and sodium cyanide share the common characteristic of extreme toxicity, their differences in physical properties, chemical behaviors, applications, and safety requirements are substantial. Understanding these distinctions is crucial for ensuring their safe and effective use in various industrial processes. Both compounds require strict regulatory compliance, careful handling, and proper management to prevent accidents, protect human health, and safeguard the environment.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- Anionic/Cationic Polyacrylamide Flocculant PAM

- ENVIRONMENTAL MANAGEMENTSYSTEM CERTIFICATE

- Booster(Detonating insensitive explosives)

- Shock Tube Detonator

- Sodium Metal, ≥99.7%

- Sodiumsulfite Technical Grade 96%-98%

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 6Oxalic acid for mining 99.6%

- 7Calcium hydroxide Industrial Grade 90%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: