DESCRIPTION

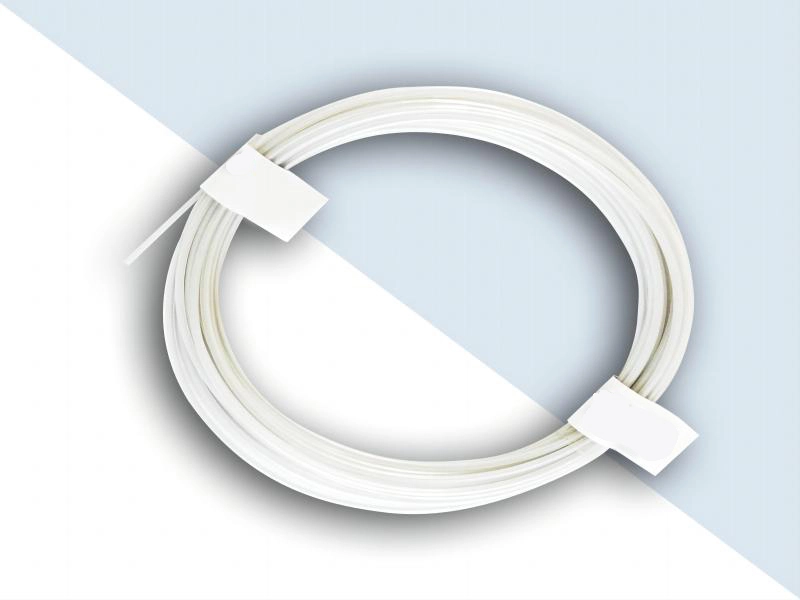

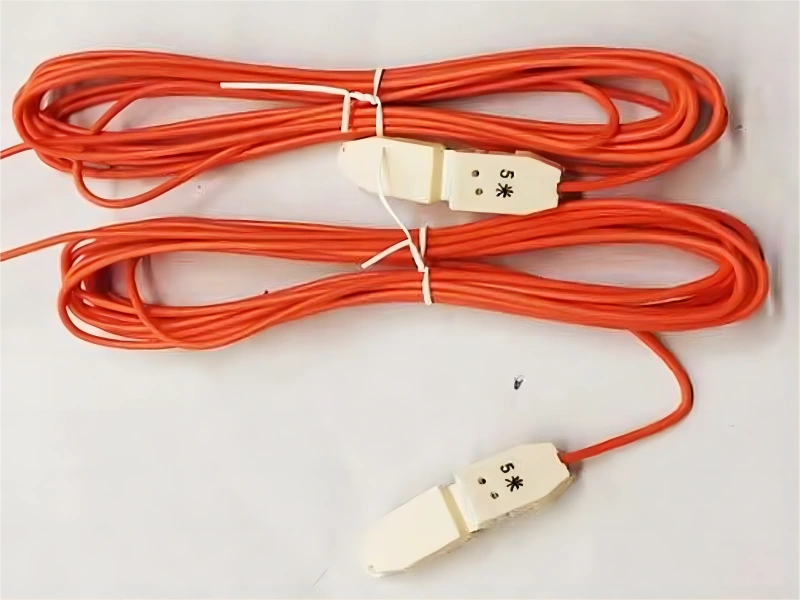

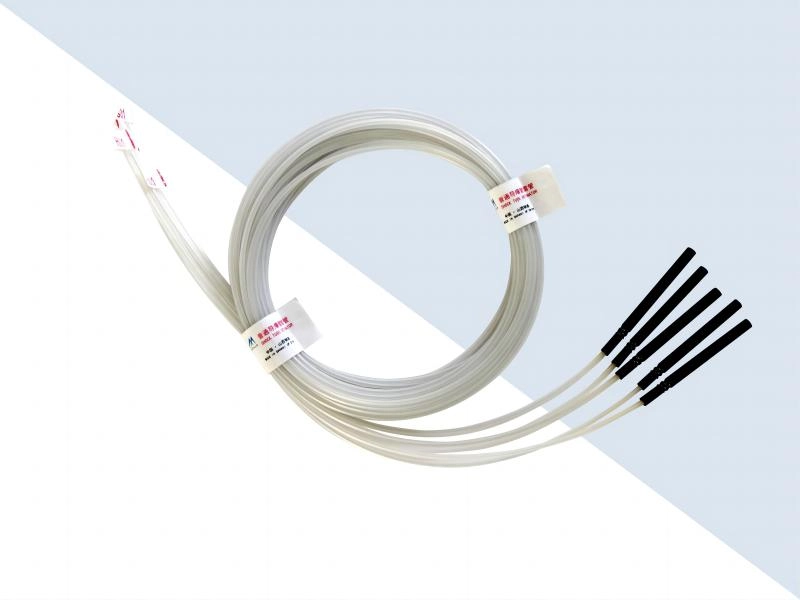

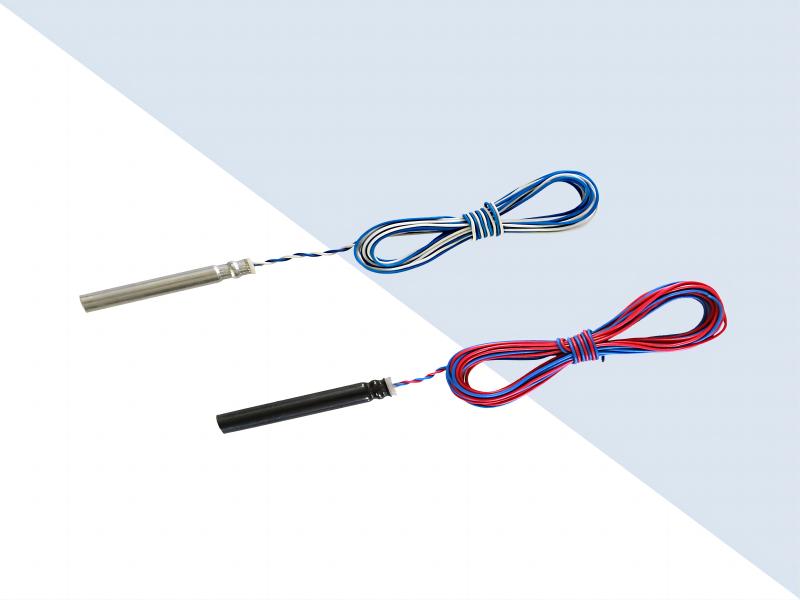

Plastic Shock Tube: Designed for applications requiring high flexibility and strength. Their detonation velocity ≥1600 m/s, which enables them to be effectively used in a variety of mining processes, including drilling, blasting and laying utility lines.

Product Details

Item | Performance |

VOD | VOD≧1600m/s, VOD Range of Same Batch≦100m/s |

Reliability of diffusing detonation | No blowout under 20℃ environment except for the initiating end |

Initiation sensitivity | 20pcs of shock tube can be completely initiated by one piece of No.8 detonator. |

Jolt test | Detonation is still good after vibrating for 5mins in the vibrating machine. |

Tensile | ≧68.6N/20℃±5℃ |

Low temperature anti-folding property | Stored in -40℃ environment for 1h, no crack, no blowout and the detonation is good. |

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- QUALITY MANAGEMENT SYSTEMCERTIFICATE

- 31%-36% HCl/Industrial Grade Hydrochloric Acid

- Seismic Electric Detonator(Anti static,Water Resistance)

- Antimonium Tartrate Potassium

- Hydrogen Peroxide

- Fertilizer magnesium sulfate/magnesium sulfate monohydrate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Oxalic acid for mining 99.6%

- 6Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: