Sodium cyanide, a highly toxic and hazardous chemical widely utilized in industries such as mining, electroplating, and chemical synthesis, demands strict adherence to safety protocols. Failure to comply with these rules can lead to severe consequences, including serious accidents, environmental contamination, and loss of life. This blog post aims to underscore the significance of following sodium cyanidesafety use rules and provide essential guidelines to ensure safe handling and usage.

Understanding Sodium Cyanide

Before delving into safety rules, it is crucial to understand the properties and hazards associated with Sodium Cyanide. Sodium cyanide is a white crystalline solid that readily dissolves in water, releasing highly toxic hydrogen cyanide gas upon contact with acids. Even minute exposure to this chemical can cause immediate health issues, ranging from respiratory distress and nausea to coma and death. Due to its extreme toxicity, any handling of Sodium cyanide must be carried out with the utmost caution and in strict accordance with safety regulations.

Key Safety Use Rules

Personal Protective Equipment (PPE)

One of the fundamental safety measures when working with sodium cyanide is wearing appropriate PPE. This includes chemical-resistant gloves, goggles, a full-face respirator with an approved filter, and protective clothing. PPE acts as a barrier between the worker and the chemical, significantly reducing the risk of exposure. Workers must ensure that their PPE is in good condition, properly fitted, and used consistently throughout the handling process.

Proper Storage

Sodium cyanide should be stored in a dedicated, locked storage area that is separate from other chemicals, especially acids. The storage area should be well-ventilated, dry, and equipped with spill containment measures. It is essential to label storage containers clearly with the chemical name, hazard warnings, and emergency contact information. Regular inspections of the storage area should be conducted to check for any signs of leakage or damage.

Handling Procedures

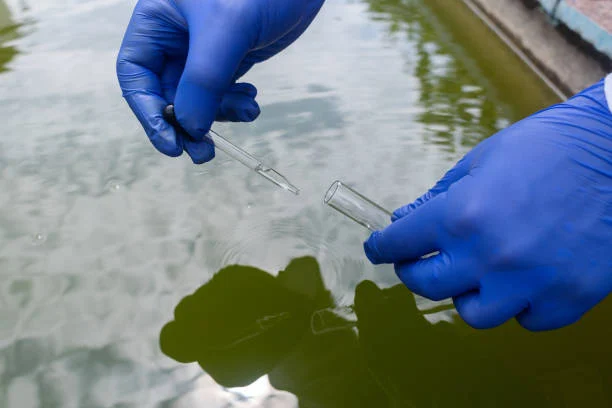

When handling sodium cyanide, workers must follow strict procedures to minimize the risk of spills and exposure. This includes using appropriate tools and equipment, avoiding direct contact with the skin and eyes, and working in a well-ventilated area. Any spills or leaks should be reported immediately, and the appropriate emergency response measures should be taken. This may involve containing the spill, neutralizing the chemical, and notifying the relevant authorities.

Training and Education

All workers who handle sodium cyanide should receive comprehensive training on its safe use, handling, and emergency procedures. Training should cover topics such as the properties and hazards of sodium cyanide, proper use of PPE, storage and handling procedures, and first aid measures in case of exposure. Regular refresher training should also be provided to ensure that workers remain up-to-date with the latest safety guidelines.

Consequences of Non-Compliance

Failure to comply with sodium cyanide safety use rules can have far-reaching consequences. Accidental exposure to sodium cyanide can result in serious health problems for workers, and in extreme cases, fatalities. Additionally, spills and leaks can contaminate the environment, posing a threat to wildlife and water sources. Non-compliance can also lead to legal penalties, including fines and lawsuits, as well as damage to a company's reputation.

Case Studies

To illustrate the importance of compliance, let's consider a few real-life case studies. In [Year], a chemical plant experienced a sodium cyanide spill due to improper storage and handling procedures. The spill resulted in the release of toxic gas, causing several workers to be hospitalized and leading to the evacuation of nearby residents. The company faced significant fines and legal action, and its reputation was severely damaged.

In another incident, a worker at a gold mine was exposed to sodium cyanide due to a lack of proper training and PPE. The worker suffered from respiratory problems and other health issues, requiring extensive medical treatment. This case highlights the importance of providing adequate training and ensuring that workers have access to the necessary safety equipment.

Conclusion

Compliance with sodium cyanide safety use rules is not only a legal requirement but also a moral obligation to protect the health and safety of workers and the environment. By understanding the hazards associated with sodium cyanide, following key safety guidelines, and providing comprehensive training, companies can significantly reduce the risk of accidents and ensure safe handling and usage of this highly toxic chemical. Remember, safety should always be the top priority when working with sodium cyanide.

If you have any questions or need further information on sodium cyanide safety use rules, please feel free to contact us. We are committed to providing you with the resources and support you need to ensure a safe working environment.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- industry Electric Detonator

- Sodiumsulfite Technical Grade 96%-98%

- Thiourea 99% high activity Professional Producer

- Pine oil 85% High Quality Pinitol oil 85% Light Yellow To Colorless Oily Liquid

- Ammonium Persulfate Industrial Grade 98.5%

- Antimonium Tartrate Potassium

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 6Oxalic acid for mining 99.6%

- 7Calcium hydroxide Industrial Grade 90%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: