Introduction

In the gold mining and extraction industry, the all - slime cyanidation process has long been a widely used method for extracting gold from ores. This process starts with grinding the entire ore into fine particles, usually with a significant proportion of particles smaller than 74 micrometers ( - 200 mesh). The resulting ore slurry is then treated with cyanide. Cyanide ions react with gold in the ore, forming soluble gold - cyanide compounds. These compounds can be further processed to recover the gold.

An important improvement to the all - slime cyanidation process is the introduction of oxygen - rich leaching. This enhancement has demonstrated great potential in improving the efficiency and effectiveness of Gold extraction.

Principle of Oxygen - Rich Intensified Cyanide Leaching

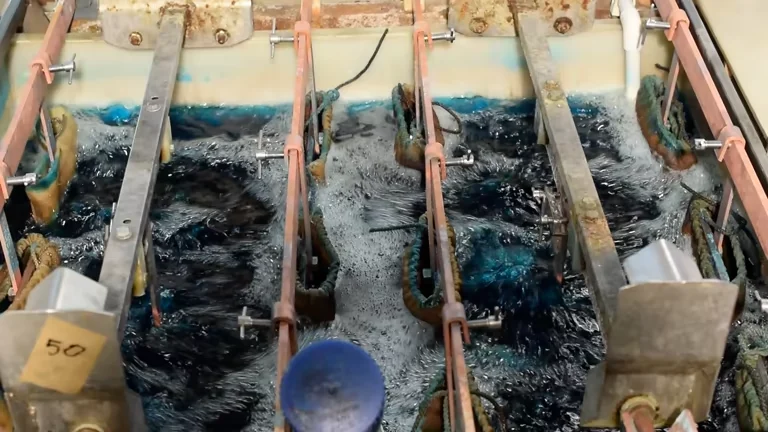

The oxygen - rich intensified gold leaching process, also known as the CIG oxygenation process, replaces the traditional practice of using compressed air in the leaching tank with pure oxygen. When pure oxygen is introduced into the leaching tank from beneath the agitator, it dissolves in the ore slurry. The core principle is that the dissolution of gold in cyanide solutions occurs through an electrochemical reaction. Oxygen acts as an oxidizing agent, which helps to dissolve gold more effectively.

Most cyanide plants operate under conditions where the ratio of cyanide ions to oxygen is greater than 6. In such situations, the speed of gold dissolution depends on how quickly oxygen can diffuse into the reaction. By using pure oxygen, the amount of dissolved oxygen in the slurry increases, which speeds up the overall reaction. Research shows that gold leaching with oxygen is around five times faster than with air.

Advantages of Oxygen - Rich Leaching in All - Slime Cyanidation

1. Increased Leaching Speed and Recovery Rate

A higher oxygen concentration in the slurry directly leads to a faster leaching speed. With quicker gold dissolution, the total leaching time can be significantly reduced. This not only boosts the daily processing capacity of the plant but also enables more efficient extraction of gold from the ore. As a result, the gold recovery rate can be improved, leading to higher yields of this precious metal.

2. Reduced Cyanide Consumption

Using pure oxygen in the leaching process can cut Cyanide consumption by anywhere from 5% to 85%. There are several reasons for this. First, when pure oxygen is used instead of air, the amount of carbon dioxide in the slurry decreases. Carbon dioxide can react with cyanide, causing it to be consumed in side reactions. With less carbon dioxide, these side reactions are minimized. Second, the much - faster leaching speed reduces the impact of other side reactions that consume cyanide. Third, pure oxygen can oxidize substances in the ore that would otherwise consume cyanide, further decreasing the amount of cyanide needed for the leaching process.

3. Smaller Equipment Requirements

If the leaching capacity remains unchanged, oxygen - rich leaching can greatly reduce the size of the leaching tank. Because the faster leaching rate allows the same amount of gold to be processed in a shorter time, a smaller reaction volume is sufficient. Reducing the size of the leaching equipment can lead to cost savings in terms of equipment purchase, installation, and the overall space required by the processing plant.

Application Cases

Case 1:

previously used the traditional all - slime cyanidation process with air aeration. Due to the complex nature of the ore, achieving high gold recovery rates was a challenge. After implementing the all - slime cyanidation oxygen - rich leaching process, remarkable improvements were seen. The leaching time was halved, and the gold recovery rate increased from 80% to 90%. Additionally, cyanide consumption decreased by 30%, resulting in significant cost savings for the mine.

Case 2:

is a large - scale gold mine with high - volume processing capabilities. By adopting the oxygen - rich leaching process in their all - slime cyanidation system, they managed to increase their daily gold production by 20%. The mine also reported a reduction in overall operating costs, mainly due to lower cyanide consumption and more efficient use of equipment. The successful implementation at [Mine Name 2] serves as an example for other mines in the region to consider upgrading their extraction processes.

Challenges and Solutions in Implementing Oxygen - Rich Leaching

1. Safety Concerns

Handling pure oxygen requires strict safety protocols. Oxygen is highly reactive, and improper handling can lead to fire or explosion risks. To address this, mines must invest in oxygen storage and delivery systems that meet safety standards. Regular safety training for employees involved in the oxygen - rich leaching process is also crucial to ensure they understand the potential hazards and how to safely operate oxygen - related equipment.

2. Equipment Compatibility

Upgrading to an oxygen - rich leaching system may require modifications to existing leaching equipment. The materials used in the construction of leaching tanks, agitators, and pipelines need to be compatible with oxygen to prevent corrosion and ensure long - term operation. In some cases, it may be necessary to replace certain components with oxygen - resistant materials like stainless steel or specialized polymers.

3. Cost of Oxygen Supply

The cost of obtaining and supplying pure oxygen can be a concern for some mines. However, the savings from reduced cyanide consumption and increased gold recovery rates often outweigh the cost of oxygen in the long term. Mines can explore various options for oxygen supply, such as on - site oxygen generation plants or long - term contracts with reliable suppliers, to make the oxygen - rich leaching process more cost - effective.

Conclusion

The all - slime cyanidation oxygen - rich leaching process offers significant benefits in the gold extraction industry. By increasing leaching speed, improving gold recovery rates, reducing cyanide consumption, and potentially minimizing equipment size, this process has the potential to enhance the profitability and sustainability of gold mines. Although there are challenges in its implementation, with appropriate safety measures, equipment upgrades, and cost - optimization strategies, more and more mines are likely to adopt this advanced leaching technology in the future. As the demand for gold continues to grow, efficient extraction methods like oxygen - rich leaching will play a vital role in meeting this demand while minimizing environmental and economic impacts.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- High Quality Sodium silicate 99% Water glass

- Unlocking the Power of Mineral Processing Chemicals: Enhancing Efficiency and Sustainability

- IPETC 95%Metal sulfide mineral collector Z-200

- Colloidal emulsion explosive

- Sodiumsulfite Technical Grade 96%-98%

- MERCURY METAL Extra Pure | CAS 7439-97-6

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Oxalic acid for mining 99.6%

- 6Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: