Introduction

In the realm of gold extraction, the cyanidation process has long been a cornerstone due to its selectivity and feasibility. However, when dealing with copper-bearing gold ores, the complexity of the mineralogy presents unique challenges. As copper, silver, and gold orebody grades globally continue to decline, and the surrounding mineralogy becomes more diversified, it is crucial to optimize the cyanidation process for these complex ores. This blog post delves into the application and research of cyanidation for copper-bearing gold ores, aiming to provide insights into effective treatment methods.

Challenges in Cyanidating Copper-Bearing Gold Ores

Mineralogical Complexity

Copper-bearing gold ores often contain a variety of minerals, including metal sulfide minerals such as pyrite, pyrrhotite, chalcopyrite, and sphalerite. Additionally, they may have ions like Fe²⁺, Cu²⁺, Zn²⁺, S²⁻, and Fe³⁺ in the ore pulp. During the cyanidation leaching process, these components can consume a large amount of cyanide and dissolved oxygen. For example, the presence of Cu²⁺ can react with cyanide, forming stable complexes, thus reducing the free cyanide available for gold dissolution. This not only increases the consumption of cyanide but also decreases the efficiency of gold leaching.

Cyanide Consumption

The high copper content in the ores leads to excessive cyanide consumption. The soluble copper in the leach liquors reacts with cyanide, causing unacceptably high operating costs. In some cases, the copper grades in the feed may change over time, as seen in the Anglo Asian Mining's Geda Bek mine in Azerbaijan. After the start-up of the agitation leach and resin - in - pulp gold ore processing plant, higher copper grades than expected led to increased cyanide consumption, despite the plant's ability to handle high copper concentrations in the leach liquors without affecting gold production significantly.

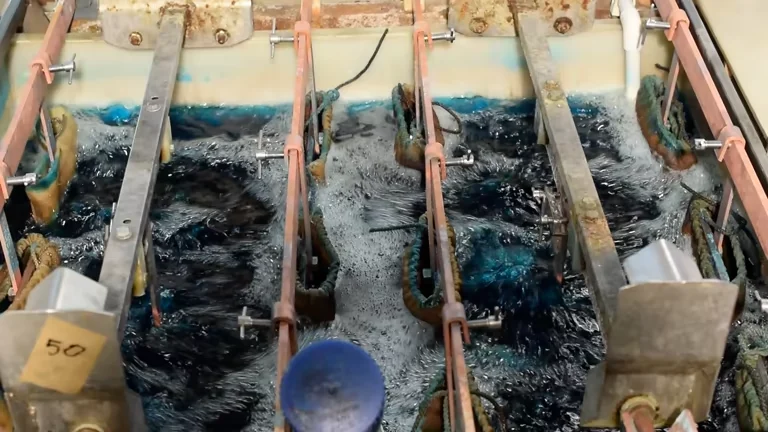

Application of Cyanidation Process for Copper-Bearing Gold Ores

Ammonia - Assisted Cyanide Leaching

One approach to address the challenges in cyanidating copper-bearing gold ores is the use of ammonia - assisted cyanide leaching. In the Geda Bek mine, ammonia was introduced into the leaching circuit to reduce cyanide consumption. This method has been found to be effective in halving the extraction of copper, thereby leading to significant reductions in cyanide consumption in the full - scale leaching system. The use of ammonia in copper - gold cyanide leach systems has a long history, dating back to 1902 when Hunt patented its use to reduce cyanide consumption during gold leaching from copper - bearing ores. The ammonia - cyanide process was used commercially to treat tailings from the Comstock Lode in Nevada and cupriferous gold ore at Dale, California.

Pretreatment of Ore Pulp

Pretreatment of the ore pulp is another important step in the cyanidation process for copper-bearing gold ores. Alkaline pretreatment can reduce the consumption of cyanide and improve the cyanide leaching rate of gold. When the ore pulp is not pretreated, the free CN⁻ in it is the least, indicating that CN⁻ is consumed by Fe²⁺, Zn²⁺, S²⁻ and other ions, and the content of Cu²⁺, Fe³⁺, Zn²⁺ ions is also the lowest. After pretreatment, the free CN⁻ in the ore pulp is relatively high, and the Cu²⁺, Fe³⁺, Zn²⁺ ions are higher than those without pretreatment, which means that the consumption of free CN⁻ after pretreatment is reduced, and the harmful ions are not consumed by CN⁻. Therefore, alkaline pretreatment before cyanide leaching can be beneficial.

Research and Optimization Directions

Development of New Reagents and Processes

Researchers are constantly exploring new reagents and processes to improve the cyanidation process for copper-bearing gold ores. For example, the use of auxiliary oxidants is an area of focus. Adding oxidants (such as pure oxygen or other oxides) during the leaching process can increase the "effective active oxygen" content in the ore pulp, improve the cyanidation leaching environment, accelerate the leaching speed, shorten the leaching time, and reduce the consumption of cyanide. The use of auxiliary oxidants has been widely promoted around the world as an optimal technology for optimizing the cyanidation process. In addition, the development of new leaching agents, such as thiosulfate, which has shown potential in leaching gold from copper-bearing gold ores with high efficiency, is also an important research direction.

Process Integration and Optimization

Integrating different processes can also lead to better results. For instance, integrating the agitation leach plant with existing heap leach/ADR/SART operations, as done in the Geda Bek mine, can make the overall process more efficient. The resin - in - pulp system, where gold is recovered from the leach pulp by contact with a gold - specific ion exchange resin, is a key part of this integration. By optimizing the combination of these processes and equipment, the overall performance of the cyanidation process for copper-bearing gold ores can be enhanced.

Conclusion

The cyanidation process for copper-bearing gold ores remains a vital method in the mining industry despite its challenges. Through strategies such as ammonia - assisted cyanide leaching, ore pulp pretreatment, and continuous research and development of new reagents and process integrations, the efficiency and economic viability of the cyanidation process can be improved. As the mining industry continues to face the challenges of declining ore grades and complex mineralogy, continuous innovation in the cyanidation process for copper-bearing gold ores will be essential to ensure sustainable gold production.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- Flexible Customer and Supplier Relations Specialist (: Indonesia)

- Sodium Sulfide Industry Grade 60% 30ppm/150ppm Yellow/ Red Flakes Na2s

- Acetone

- Sodium Persulfate,Sodium Persulphate,supplier 99.00%

- Thiourea 99% high activity Professional Producer

- Phthalic anhydride

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Oxalic acid for mining 99.6%

- 6Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: