1. Introduction

Sodium Cyanide is a highly toxic substance. In accordance with the "Regulations on the Safety Management of Hazardous Chemicals" (Decree No. 591 of the State Council) issued by the State Council in March 2011. the inspection and quarantine department is responsible for the inspection of imported and exported hazardous chemicals and their packaging. To ensure the effective development of relevant inspection and quarantine business and standardize the inspection and supervision of imported and exported hazardous chemicals and their packaging, specific inspection procedures have been formulated. This article mainly elaborates on the inspection procedures for the import and export of Sodium Cyanide.

2. Requirements for Inspection Application

When the applicant applies to the inspection and quarantine institution for inspection, it should declare according to the name in the "List of Hazardous Chemicals" (2002 version). At the same time, the following documents and materials should also be provided, and the content should be accurate and consistent with each other:

"Declaration of Compliance of Export Hazardous Chemical Production Enterprises" or "Declaration of Compliance of Import Hazardous Chemical Business Enterprises";

The classification and identification report of the hazardous characteristics of exported sodium cyanide, for example, see Appendix A;

Samples of Chinese hazardous publicity labels and Safety Data Sheets (SDS) for exported Sodium cyanide, for example, see Appendix B and Appendix C;

"Inspection Results Sheet of Packaging Performance for Entry - Exit Goods" for exported sodium cyanide;

Chinese hazardous publicity labels and Safety Data Sheets (SDS) for imported sodium cyanide, for example, see Appendix B and Appendix C;

Other relevant materials.

3. Requirements for Document Review

3.1 Product Information Consistency

The component information, physical properties, chemical properties, etc. of the product should be consistent with those in 5.1b), 5.1c), 5.1e) or 5.1f).

3.2 Packaging Verification for Exported Packaged Sodium Cyanide

For exported packaged sodium cyanide, the "Inspection Results Sheet of Packaging Performance for Entry - Exit Goods" should be verified.

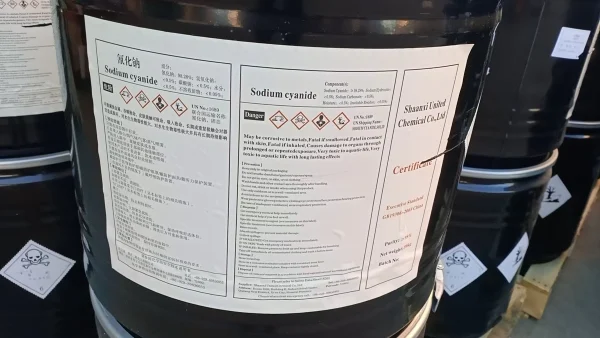

3.3 Hazardous Publicity Label Requirements

The hazardous publicity label of sodium cyanide should meet the requirements of the "Globally Harmonized System of Classification and Labelling of Chemicals" (GHS). For imported products, it should also meet the requirements of GB 15258. The label content should be complete and accurate. The label example is shown in Appendix B.

3.4 Safety Data Sheet Requirements

The Safety Data Sheet should have complete and accurate information. The Safety Data Sheet example is shown in Appendix C.

4. Inspection Requirements

4.1 Inspection Lot

The products of the same manufacturer, the same exporting country (or region), and the same specification declared for inspection are regarded as one inspection lot.

4.2 Sampling

For products, determine the sampling quantity and sample quantity according to GB/T 6678 and conduct sampling according to the requirements of GB/T 6679. Sampling shall be carried out in accordance with the relevant safety protection requirements of GB/T 3723.

The sampling quantity for on - site verification of hazardous publicity information is shown in Table 1.

4.3 Packaging and Transportation Warning Labels

On the prominent position of the product's transport packaging, packaging and transportation warning labels that comply with the "Regulations and Model Regulations on the Transport of Dangerous Goods" (UNRTDG) should be affixed, attached, or sprayed. The style is shown in Figure 1.

4.4 Packaging Requirements

The product should determine the appropriate packaging, design model, and unit mass in accordance with the requirements of the "Regulations and Model Regulations on the Transport of Dangerous Goods" (UNRTDG). The packaging requirements for sodium cyanide are shown in Table 2.

4.5 Hazardous Publicity Information Requirements

On the prominent position of the product packaging, hazardous publicity labels that comply with the "Globally Harmonized System of Classification and Labelling of Chemicals" (GHS) should be affixed, attached, or sprayed. For imported products, it should also meet the requirements of GB 15258. The label should be firm, and the label information content should at least include basic elements such as product identification, pictograms, signal words, hazard statements, and precautionary statements, and should be true and accurate.

The manufacturer/supplier and product information listed in the Safety Data Sheet attached to the product should be true, complete, and effective, and consistent with those in 5.1c) or 5.1e). The information in the Safety Data Sheet should be complete and accurate, and should at least include the 16 basic information items specified in the "Globally Harmonized System of Classification and Labelling of Chemicals" (GHS).

5. Testing Requirements

5.1 Product Component Testing

Product component testing shall be carried out in accordance with GB 19306 and GB/T 23765.

5.2 Product Classification Testing

Product classification testing shall be carried out in accordance with SN/T 1828.9. SN/T 3656.6. the "Test and Standard Manual for the Transport of Dangerous Goods" or the "Globally Harmonized System of Classification and Labelling of Chemicals" (GHS).

6. Inspection Process

6.1 Data Review

Verify whether the declared materials meet the requirements of 5.1. and review whether the relevant technical content of the hazardous publicity label and the Safety Data Sheet meets the requirements of 5.2.3 and 5.2.4.

6.2 On - site Inspection

Check whether the product name, hazard category or item, hazard type and category, component composition information, physical and chemical properties, etc. meet the requirements of 5.1a), 5.1b), 5.1c) or 5.1e).

Check whether the packaging and transportation warning labels on the packages are consistent with those in 5.3.3 and meet the requirements of SN/T 0730.3 or SN/T 3221.

Check whether the product's Safety Data Sheet (SDS) and hazardous publicity label are complete, and whether the corresponding contents are consistent and meet the requirements of 5.1b), 5.1c), 5.1d), 5.1e) and 5.3.5.

Check whether the type, specification, unit weight (volume and gross/net weight) of the packaging are consistent with the information in the inspection application materials and meet the requirements of 5.3.4.

Check whether the mark on the packaging is for Class I packaging.

Check whether the appearance of the packaging is intact, clean, free of residues, contamination, or leakage.

7. Conclusion

The import and export inspection procedures for sodium cyanide cover various aspects from the initial inspection application to the final on - site inspection and testing. These procedures play a crucial role in ensuring the safe cross - border movement of this highly dangerous chemical. Both import and export enterprises need to strictly abide by these procedures to avoid potential safety risks and legal issues.

- Random Content

- Hot content

- Hot review content

- Flexible Customer and Supplier Relations Specialist (Location: India)

- The Essential Guide to Sodium Cyanide: Usage Cases and Sourcing

- Dithiophosphate 25S

- Collector BLK-301/Composite Flotating Active Matter ≥60%

- Oxalic acid for mining 99.6%

- Powdery emulsion explosive

- High-strength Shock tube(VOD≧2000m/s)

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: