Sodium cyanide is a highly toxic chemical widely used in industries such as mining, electroplating, and chemical manufacturing. Due to its extreme toxicity and potential to cause significant harm to human health and the environment, transporting Sodium Cyanide demands the utmost care and strict adherence to safety protocols. This article outlines the crucial precautions that must be taken when transporting this dangerous substance.

Regulatory Compliance

Permits and Licensing: Before any transportation of sodium cyanide can occur, it is essential to obtain all the necessary permits and licenses from the relevant regulatory authorities. These permits typically involve demonstrating compliance with safety regulations, having appropriate emergency response plans in place, and showing that the transport personnel are adequately trained. For example, in many countries, companies need to apply for a special hazardous materials transportation permit, which may require regular renewals and inspections.

Adherence to Regulations: Comply with national and international transportation regulations. In the United States, the Department of Transportation (DOT) has strict rules regarding the packaging, labeling, and transportation of hazardous materials like Sodium cyanide. The International Maritime Dangerous Goods (IMDG) Code must be followed for ocean transport, and the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) applies to road transport in Europe. These regulations cover aspects such as maximum allowable quantities per vehicle or container, speed limits, and routing restrictions.

Packaging and Containment

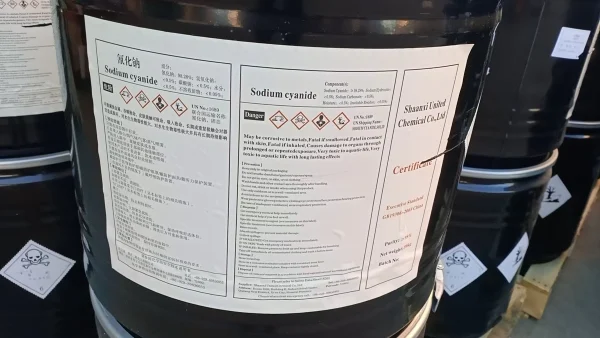

Robust Packaging: Use packaging materials that are specifically designed to handle the corrosive and toxic nature of sodium cyanide. The packaging should be made of materials such as high - density polyethylene (HDPE) or steel, depending on the form of sodium cyanide (solid or liquid). Solid sodium cyanide is often transported in sealed metal drums or fiberboard boxes lined with plastic. Liquid sodium cyanide requires more specialized packaging, such as stainless - steel tanks or corrosion - resistant plastic containers.

Sealing and Venting: Ensure that all packages are tightly sealed to prevent any leakage. In the case of liquid sodium cyanide, the seals must be able to withstand pressure changes during transportation. Some containers may also require proper venting systems to release any built - up pressure safely. However, venting must be designed in a way that prevents the escape of toxic fumes into the environment.

Labeling and Marking: Clearly label all packages with the appropriate hazard warnings. Labels should indicate that the contents are sodium cyanide, along with the “Toxic” symbol and information about the proper handling in case of an emergency. Markings should also include the UN number (1689 for solid sodium cyanide and 1935 for sodium cyanide solutions), which helps emergency responders quickly identify the substance in case of an accident.

Transportation Environment

Temperature and Humidity Control: Sodium cyanide should be transported in an environment where temperature and humidity are carefully regulated. High temperatures can increase the risk of decomposition or chemical reactions, while excessive humidity can cause the formation of toxic hydrogen cyanide gas. For example, during summer months, trucks may need to be equipped with temperature - controlled compartments to keep the sodium cyanide within a safe temperature range.

Avoidance of Contaminants: Keep sodium cyanide away from other substances that could react with it. It should not be transported in the same vehicle as acids, oxidizing agents, or water - reactive materials. A small leak of an acid near a container of sodium cyanide could lead to the production of highly toxic hydrogen cyanide gas, which is extremely dangerous to both the transport workers and the surrounding environment.

Personnel Training and Safety

Specialized Training: All personnel involved in the transportation of sodium cyanide, including drivers, loaders, and escorts, must receive specialized training on handling hazardous materials. This training should cover the properties of sodium cyanide, emergency response procedures, and the proper use of personal protective equipment (PPE). Training should be regularly updated to keep up with any changes in safety regulations or best practices.

Personal Protective Equipment: Provide and ensure the use of appropriate PPE. Workers should wear chemical - resistant suits, gloves, goggles, and respirators. The respirators should be specifically designed to filter out toxic fumes such as hydrogen cyanide. PPE must be regularly inspected for any signs of wear and tear and replaced as needed.

Emergency Response Planning: Have a comprehensive emergency response plan in place. This plan should include procedures for dealing with spills, leaks, or accidents. Workers should know how to quickly isolate the affected area, notify the appropriate authorities, and initiate first - aid measures if necessary. Emergency drills should be conducted regularly to ensure that all personnel are familiar with their roles and responsibilities during an emergency.

Route Planning and Monitoring

Safe Route Selection: Plan the transportation route carefully, avoiding densely populated areas, schools, hospitals, and areas with sensitive environmental receptors. Routes should be chosen based on factors such as traffic volume, road conditions, and the availability of emergency services. In some cases, special permits may be required to transport sodium cyanide through certain areas.

Vehicle Monitoring: Use tracking devices to monitor the location and movement of the vehicle transporting sodium cyanide. This allows for real - time tracking in case of any deviations from the planned route or in the event of an emergency. Some advanced systems can also monitor the condition of the cargo, such as temperature and pressure within the containers.

Transporting sodium cyanide is a complex and high - risk operation that requires meticulous planning, strict compliance with regulations, and a commitment to safety at every stage. By following these precautions, the risks associated with transporting this highly toxic substance can be minimized, protecting both human lives and the environment.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- Sodium Isobutyl Xanthate SIBX 90%

- Oxalic acid for mining 99.6%

- Triethanolamine(TEA)

- Manganese sulfate

- butyl vinyl ether

- Lithium hydroxide 99% Solid

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 6Oxalic acid for mining 99.6%

- 7Calcium hydroxide Industrial Grade 90%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: