Introduction

The textile industry heavily relies on Dyeing processes to add color and aesthetic appeal to fabrics. Among the various chemicals used, Sodium sulfide plays a crucial role, especially in certain types of dyeing methods. This article delves into the specific functions and significance of sodium sulfide in the context of dyeing.

Chemical Properties of Sodium Sulfide

Sodium sulfide, with the chemical formula Na₂S (commonly encountered as its hydrate Na₂S·9H₂O), is a colorless, water - soluble salt. When dissolved in water, it forms strongly alkaline solutions. This alkalinity is a key property that contributes to its functionality in dyeing processes. Additionally, sodium sulfide has strong reducibility, which allows it to participate in redox reactions that are fundamental to many dyeing mechanisms.

Sodium Sulfide in Sulfur Dye Synthesis

Promoting Dye Intermediate Conversion

Sulfur dyes are important in the textile industry, especially for producing dark colors like black and navy. Sodium sulfide is integral in the synthesis of these dyes. It promotes the conversion of dye intermediates. For example, in the reaction of aromatic amines or phenols with sulfur or polysulfides to form Sulfur dyes, sodium sulfide acts as a reactant that helps drive the reaction forward. It may participate in reactions that introduce sulfur - containing groups into the dye structure, which are essential for the color - forming properties of the final dye product.

Impact on Final Dye Product Performance

The presence of sodium sulfide during sulfur dye synthesis also impacts the performance of the final dye. It can influence properties such as color fastness, lightfastness, and the overall color intensity of the dye. By controlling the reaction conditions with sodium sulfide, manufacturers can optimize these properties to meet the demands of different textile applications. For instance, the right amount of sodium sulfide can enhance the lightfastness of the dye, ensuring that the dyed fabric retains its color when exposed to sunlight for extended periods.

Sodium Sulfide in Dyeing Processes

As a Reducing Agent

1.Reducing Sulfur Dyes for Uptake

Sulfur dyes, in their native state, are insoluble in water and cannot directly attach to the fabric. Sodium sulfide serves as a powerful reducing agent. It reduces the sulfur dyes, breaking the sulfur - sulfur bonds within the dye molecules. This reduction process converts the insoluble sulfur dyes into soluble, colorless forms known as leuco - compounds or sodium salt of the leuco - form (in an alkaline medium). For example, in the case of a typical sulfur black dye, sodium sulfide reacts with the dye molecule, providing electrons to break the sulfur - sulfur linkages and form a soluble species that can be absorbed by the fabric.

2.Maintaining the Reducing Environment

During the dyeing process, it is crucial to maintain a reducing environment to prevent the premature oxidation of the reduced dye. Sodium sulfide continues to act as a reducing agent throughout the process, ensuring that the leuco - form of the dye remains stable. This is essential because if the leuco - form is oxidized too soon, it will revert back to its insoluble state and will not be able to penetrate the fabric effectively. The reducing power of sodium sulfide is such that it can counteract any oxidizing agents that may be present in the dye bath, such as dissolved oxygen from the air.

As an Alkalinity Provider

1.Dye Solubilization

In addition to its reducing function, sodium sulfide contributes to the alkalinity of the dye bath. The alkaline nature of the solution helps in solubilizing the reduced sulfur dyes. When sulfur dyes are reduced by sodium sulfide, they form leuco - acids. The alkaline environment provided by sodium sulfide then neutralizes these leuco - acids, converting them into their sodium salt forms, which are highly soluble in water. This solubilization is essential for the uniform distribution of the dye in the dye bath and its subsequent uptake by the fabric.

2.Fiber Swelling and Dye Penetration

The alkalinity from sodium sulfide also causes the fibers in the fabric to swell slightly. For natural fibers like cotton, the alkaline solution disrupts the hydrogen bonding within the fiber structure, causing it to become more porous. This swelling allows the reduced dye molecules to penetrate more easily into the interior of the fiber. As a result, the dyeing process becomes more efficient, and the color penetration and fastness are improved.

As a Dyeing Aid for Improved Quality

1.Enhancing Dye Uptake and Levelness

Sodium sulfide can enhance the uptake of dyes onto the fabric. The sodium ions released from sodium sulfide in the dye bath can interact with the negatively charged sites on the fiber surface (in the case of cellulosic fibers like cotton, which have a slight negative charge due to the presence of hydroxyl groups). This interaction helps to increase the attraction between the dye molecules and the fiber, promoting better dye uptake. Moreover, it can also contribute to more even dye distribution (levelness) on the fabric. By facilitating the movement of dye molecules towards the fiber surface and into the fiber, sodium sulfide helps to prevent the formation of dye concentration gradients, which can lead to uneven coloration.

2.Improving Color Fastness

The use of sodium sulfide in the dyeing process can significantly improve the color fastness of the dyed fabric. The reduced sulfur dyes, after being absorbed by the fabric, are then oxidized to reform the insoluble sulfur dye within the fiber structure. The presence of sodium sulfide during the initial reduction step ensures that the dye is evenly distributed within the fiber. When the dye is oxidized and fixed in place, this even distribution results in better color fastness to washing, rubbing, and light exposure. For example, fabrics dyed with sulfur dyes using sodium sulfide as a reducing agent tend to retain their color better after multiple wash cycles compared to those dyed with other reducing agents or under improper conditions.

Removing Fiber Impurities in Pre - treatment

1.Desizing and Degumming

In the pre - treatment of fibers before dyeing, sodium sulfide can be used to assist in removing impurities. For natural fibers such as silk, which contains sericin (a gum - like substance), and cotton, which may have sizing agents added during textile manufacturing, sodium sulfide can help in the desizing and degumming processes. The alkaline nature of sodium sulfide can break down the sericin in silk and the sizing agents in cotton. This not only prepares the fiber surface for better dye uptake but also improves the overall quality of the fabric.

2.Scouring and Cleaning

Sodium sulfide can also be used in scouring processes to remove oils, fats, and other contaminants from the fiber surface. In a scouring bath containing sodium sulfide, the alkaline environment helps to emulsify and saponify the fatty substances present on the fiber. This results in a cleaner fiber surface, which is essential for achieving uniform dyeing. By removing these impurities, sodium sulfide ensures that the dye molecules can directly interact with the fiber without any interference from surface contaminants.

Optimal Usage and Considerations

Dosage Requirements

The amount of sodium sulfide used in dyeing processes varies depending on several factors, including the type of dye, the fabric being dyed, and the desired color depth. Generally, for sulfur dyeing, the dosage of sodium sulfide is typically in the range of 20% - 100% of the weight of the dye. However, careful optimization is required. Using too little sodium sulfide may result in incomplete reduction of the dye, leading to poor color development and low dye uptake. On the other hand, excessive use can cause problems such as over - reduction, which may affect the color quality and also lead to environmental pollution due to the excess sulfide in the effluent.

Environmental Impact

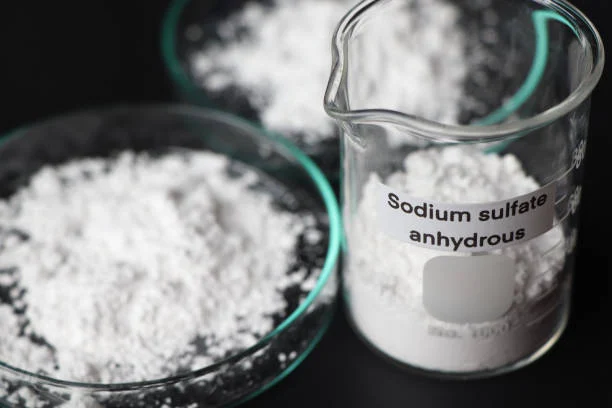

Sodium sulfide use in the dyeing industry does have environmental implications. When discharged into water bodies, sulfide ions can react with water and oxygen to form hydrogen sulfide gas, which has a strong, unpleasant odor and is toxic to aquatic life. To mitigate this, proper wastewater treatment methods are necessary. These may include aeration to oxidize sulfide ions to less harmful sulfate ions, or the use of chemical precipitation methods to remove sulfide as metal sulfide precipitates. Additionally, efforts are being made to develop more sustainable dyeing processes that minimize the use of sodium sulfide or find alternative, more environmentally friendly reducing agents.

Conclusion

Sodium sulfide is an indispensable chemical in the dyeing processes of the textile industry. Its unique chemical properties, as a reducing agent, alkalinity provider, and dyeing aid, make it essential for the synthesis and application of sulfur dyes. It plays a crucial role in ensuring the quality of dyed fabrics, from promoting dye uptake and levelness to improving color fastness. However, its usage also requires careful consideration to balance its benefits with environmental concerns. As the textile industry continues to evolve towards more sustainable practices, the role of sodium sulfide may need to be re - evaluated, and efforts to develop alternative technologies that can achieve similar dyeing results with reduced environmental impact will be of great importance.

- Random Content

- Hot content

- Hot review content

- 31%-36% HCl/Industrial Grade Hydrochloric Acid

- Dithiophosphate 25S

- Powdery emulsion explosive

- Ammonium Chloride 99.5% Mining Collector

- Acetone

- Calcium Peroxide 60% Assay Yellowish Tablet

- Potassium Permanganate – Industrial Grade

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: