In the world of Gold Mining, the extraction of gold from ore is a complex and fascinating process. One chemical that plays a pivotal role in this process is Sodium Cyanide. For over a century, sodium cyanide has been an essential component in the extraction of gold from ore, and to this day, it remains the most efficient extraction method in most gold mining operations.

The Basics of Sodium Cyanide

Sodium cyanide (NaCN) is a compound that contains the cyano group, which consists of a triple - bonded carbon and nitrogen. It can exist in both solid and liquid forms. Solid Sodium cyanide is typically produced as a white crystalline briquette, also known as a “cyanoid.” These briquettes are highly soluble, making them easy to use in the mining process. Liquid sodium cyanide, on the other hand, is delivered to mine sites via purpose - built ISO tanks suitable for road or rail transport.

How Sodium Cyanide is Used in Gold Mining

The process of using sodium cyanide to extract gold from ore is known as Cyanide Leaching or cyanidation. Here’s a step - by - step overview of how this process works:

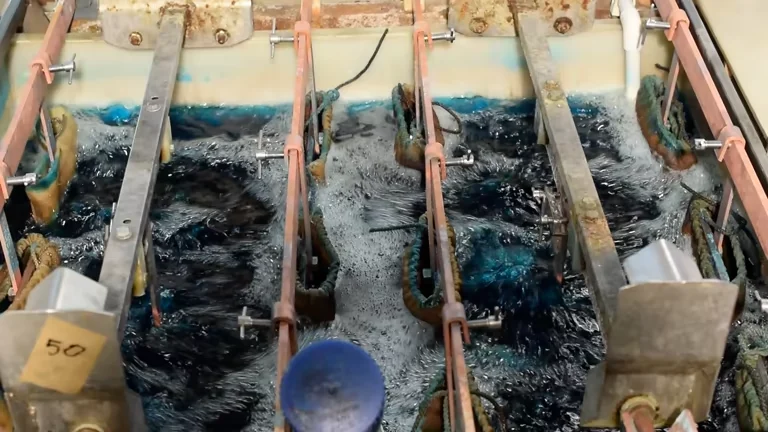

Ore Preparation: First, the gold - bearing ore is crushed into a fine powder using industrial machinery. This increases the surface area of the ore, allowing for better contact with the sodium cyanide solution.

Leaching: The crushed ore is then added to a carefully - monitored solution of sodium cyanide. During this process, the gold molecules form very strong bonds with the sodium cyanide, becoming water - soluble. The chemical reaction can be represented by the equation: 4 Au + 8 NaCN+O₂ + 2 H₂O = 4 Na(Au(CN)₂)+4 NaOH. In this reaction, gold reacts with sodium cyanide, oxygen, and water to form a soluble gold - cyanide complex, sodium aurocyanide (Na(Au(CN)₂)).

Separation: After the gold has been dissolved into the solution, the next step is to separate it from the remaining ore and other impurities. One common method is to use zinc to precipitate the gold out of the solution. Zinc reacts with the gold - cyanide complex, displacing the gold and forming zinc - cyanide complex, thus turning the gold back into a solid form. Another method is to use activated carbon to adsorb the gold - cyanide complex from the solution. The gold - laden carbon is then further processed to recover the gold.

Advantages of Using Sodium Cyanide in Gold Mining

Cost - Effectiveness: Sodium cyanide is relatively inexpensive compared to some other methods of Gold Extraction. This makes it an attractive option for mining companies, especially when dealing with large - scale operations or low - grade ores.

High Efficiency: Cyanide leaching can achieve high gold extraction rates, often exceeding 90% in many cases. This means that more gold can be recovered from the ore, increasing the profitability of the mining operation.

Solubility: Sodium cyanide has good solubility in water, allowing it to quickly spread and react with the gold in the ore, which helps to speed up the extraction process.

Safety and Environmental Considerations

It’s important to note that sodium cyanide is a highly toxic chemical. However, the mining industry has strict safety protocols in place to ensure the safe handling of sodium cyanide. In fact, in North America and Australia, there has not been a cyanide - related death among mine employees in over 100 years. When handling sodium cyanide, workers are required to wear appropriate protective gear, such as masks to protect against airborne dust or gasses containing trace amounts of cyanide.

From an environmental perspective, the main concern is the potential for cyanide to leach into surface water. Fish are much more sensitive to cyanide than humans, and improper use of cyanide can have a detrimental effect on native ecosystems. To mitigate this risk, mining companies use various methods to manage and treat cyanide - containing solutions. For example, they may use on - site treatment plants to detoxify cyanide before discharging any water. Additionally, many mines have containment systems in place to prevent the accidental release of cyanide - containing solutions.

Conclusion

Sodium cyanide has been, and continues to be, a crucial chemical in the gold mining industry. Its ability to efficiently extract gold from ore at a relatively low cost has made it an integral part of modern gold mining operations. While safety and environmental concerns are associated with its use, the mining industry has made significant progress in developing safe handling procedures and effective environmental management strategies. As technology continues to evolve, it will be interesting to see if new methods of gold extraction emerge, but for now, sodium cyanide remains a key player in the quest to unlock the value of gold from ore.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- QUALITY MANAGEMENT SYSTEMCERTIFICATE

- Flexible Customer and Supplier Relations Specialist (Location: India)

- Powdery emulsion explosive

- Magneto Electric Detonator(Anti stray current)

- Calcium Peroxide 60% Assay Yellowish Tablet

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Oxalic acid for mining 99.6%

- 6Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: