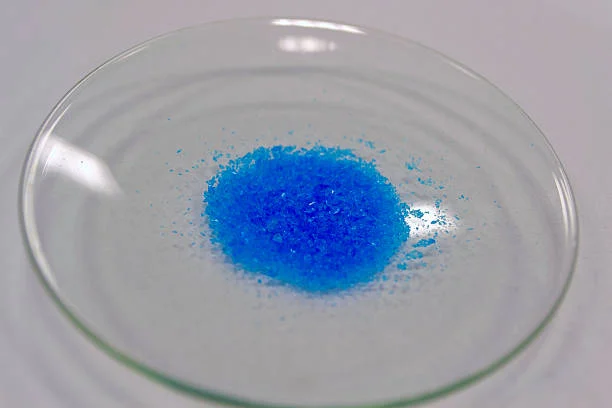

In the complex and vital field of Mineral processing, various chemical reagents play crucial roles in optimizing the separation and extraction of valuable minerals. Copper sulfate, with its distinct chemical properties, has emerged as a highly significant reagent in this industry. This article delves into the multifaceted functions of Copper sulfate in mineral processing, exploring its mechanisms and applications.

Activation of Minerals

One of the primary and most well - known roles of copper sulfate in mineral processing is its function as an activator. In sulfide ore Flotation, for example, it has a remarkable Activation effect on several minerals such as sphalerite, stibnite, pyrite, and pyrrhotite, with a particularly strong impact on sphalerite.

Activation Mechanisms

1.Metathesis Reaction to Form an Activation Film

When copper sulfate is used to activate sphalerite, a metathesis reaction occurs. The radius of divalent copper ions is similar to that of zinc ions, and the solubility of copper sulfide is much smaller than that of zinc sulfide. As a result, a layer of copper sulfide film can be formed on the surface of sphalerite. After the copper sulfide film is formed, it can easily interact with Collectors such as xanthates. Xanthates have a strong affinity for copper sulfide, which enhances the hydrophobicity of the sphalerite surface, making it easier for the mineral to attach to air bubbles and float, thus activating the sphalerite.

2.Removing Inhibitors and Forming an Activation Film

In some cases, minerals may be inhibited by other substances. For instance, when Sodium Cyanide is used as an inhibitor in the flotation process, it can form stable zinc - cyanide complex ions on the surface of sphalerite, which suppresses the flotation of sphalerite. However, copper - cyanide complex ions are more stable than zinc - cyanide complex ions. When copper sulfate is added to the sphalerite slurry inhibited by cyanide, the cyanide radicals on the surface of the sphalerite fall off, and the free copper ions then react with the sphalerite to form an activation film of copper sulfide, thereby re - activating the sphalerite for flotation.

Regulation of Slurry pH

Copper sulfate also serves as a regulator in the mineral processing slurry, particularly in terms of pH adjustment. The pH value of the slurry is a critical factor that affects the surface properties of minerals and the performance of flotation reagents.

When copper sulfate is added to the slurry, it can undergo hydrolysis in water. The resulting sulfuric acid can increase the hydrogen ion concentration in the slurry, thus lowering the pH value. At an appropriate pH value, copper sulfate can react with hydrogen ions on the mineral surface to form chemical substances that combine with the mineral surface. This reaction can increase the hydrophilicity and buoyancy of the mineral, promoting the flotation effect. For example, in some gold - bearing ores, adjusting the pH of the slurry with copper sulfate can enhance the interaction between the gold - bearing minerals and the collectors, improving the flotation recovery of gold.

Inhibition of Unwanted Minerals

In addition to activation, copper sulfate can also function as an inhibitor in certain situations. In the flotation process, it is often necessary to separate the target minerals from other unwanted minerals. Copper sulfate can be used to inhibit the flotation of non - target minerals.

When added to the slurry, copper sulfate can form anions that are adsorbed on the surface of other minerals that do not require flotation. This adsorption reduces the hydrophilicity and buoyancy of these non - target minerals, preventing them from being floated together with the target minerals. For example, in a flotation system where the goal is to separate gold minerals from certain gangue minerals, adding copper sulfate inhibitors to the slurry can keep the gangue minerals at the bottom of the flotation cell while allowing the gold minerals to float to the surface with the help of collectors and bubbles.

Modification of Mineral Surfaces

Copper sulfate can act as a mineral surface modifier, changing the chemical and physical properties of mineral surfaces. In gold ore flotation, the electrical properties and hydrophilicity of the mineral surface are key factors affecting flotation efficiency.

In the mineral slurry, copper sulfate can form copper - containing ions. These ions can react with metal ions on the surface of the mineral, altering its surface chemical properties. For example, on the surface of some gold - bearing minerals with a certain oxide layer, copper - containing ions can react with the metal ions in the oxide layer, forming new chemical compounds on the surface. This can change the surface charge and chemical reactivity of the mineral.

Moreover, copper sulfate can also affect the hydrophilicity of mineral surfaces. By increasing the contact area between minerals and water, it can improve the dispersion of minerals in the slurry. This enhanced dispersion can be beneficial for the subsequent action of collectors. When collectors are added, they can more effectively interact with the modified mineral surfaces, promoting the attachment of minerals to air bubbles and ultimately improving the flotation effect of gold mines.

Conclusion

In summary, copper sulfate plays a diverse and essential role in the mineral processing industry. As an activator, it can significantly enhance the flotation performance of minerals such as sphalerite by forming activation films or removing inhibitors. As a regulator, it helps optimize the slurry pH, which is crucial for the proper functioning of the flotation process. As an inhibitor, it can selectively prevent the flotation of unwanted minerals, improving the purity of the final concentrate. And as a mineral surface modifier, it can change the chemical and physical properties of mineral surfaces, enhancing the interaction between minerals and flotation reagents. The proper use of copper sulfate in mineral processing not only improves the efficiency of mineral separation but also contributes to the sustainable and economic utilization of mineral resources.

- Random Content

- Hot content

- Hot review content

- China factory Sulfuric Acid 98%

- QUALITY MANAGEMENT SYSTEMCERTIFICATE

- Digital Electronic Detonator(Delay time 0~ 16000ms)

- Sodium Persulfate,Sodium Persulphate,supplier 99.00%

- Ammonium Persulfate Industrial Grade 98.5%

- Manganese sulfate

- Phosphoric Acid 85% (Food grade)

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: