Strictly speaking, the cyanidation process does not fall under the category of mineral processing but should be classified as hydrometallurgy. The use of cyanidation to extract gold is the most common method in the world. Its prinCIPle relies on the complexation of cyanide ions with free gold to form gold cyanide, thereby achieving the dissolution of gold. We know that gold in nature exists in a free state; even when it is encapsulated within other minerals, it remains elemental gold once exposed. Therefore, we can say that the effectiveness (recovery rate) of the cyanidation process in extracting gold, to some extent, depends on the ability to liberate the encapsulated gold.

The CIL (Carbon In Leach) leaching process, also known as carbon leaching for gold extraction, is a process that involves adding activated carbon to the pulp and simultaneously conducting leaching and gold adsorption. This simplifies the two steps of cyanide leaching of the pulp and activated carbon adsorption found in the CIP (Carbon In Pulp) process into one step, reducing losses while lowering management costs. Compared to the traditional CCD process, it saves 66% of investment costs, making it the preferred process for modern gold ore processing.In the carbon pulp process, "carbon" and "pulp" refer to activated carbon and the mineral pulp, respectively, rather than a suspension of carbon as we might typically think. Depending on the timing of the activated carbon's introduction, we refer to the process of leaching followed by adsorption as the carbon pulp method (CIP), while simultaneous leaching and adsorption is called the carbon leaching method (CIL). Due to its more effective utilization of production equipment, an increasing number of cyanide plants are adopting this method. Its main advantages include eliminating the need for washing the pulp and solid-liquid separation, as it directly uses granular activated carbon to adsorb gold from the pulp, replacing the washing, solid-liquid separation, and clarification, degassing, and zinc replacement operations of the leachate. This significantly simplifies the industrial production process, improves efficiency, and greatly reduces equipment and infrastructure investment.

The cyanidation process requires strict grinding fineness.

For typical gold-bearing quartz vein oxidized ores, due to the poor floatability of the gold-bearing minerals, it is generally difficult to achieve good mineral processing indicators using flotation methods. However, by utilizing the carbon pulp process, it is possible to achieve a total recovery rate of over 93% under the condition of minimal harmful impurities.

As mentioned earlier, the effectiveness of the cyanidation process depends on the ability to liberate encapsulated gold, making grinding particularly important in the preparatory operations of carbon pulp plants. In common carbon pulp plants, the grinding fineness suitable for cyanidation typically requires 80-95% of the material to be finer than -0.074 mm. In some mines with disseminated mineral distribution, the requirement may even be for over 95% to be finer than -0.037 mm. This indicates that achieving the required fineness in a single stage of grinding in carbon pulp plants is quite challenging, often necessitating two or even three stages of grinding.

The control of grinding concentration is mainly achieved by adjusting the feed water volume, ore feed amount, and return sand ratio. If the grinding concentration is too high, the feed water volume should be increased, the ore feed amount in the two-stage closed-circuit grinding process should be reduced, and the return sand ratio should be increased, and vice versa. The control of overflow concentration can be managed by adjusting the overflow feed water volume, the height of the overflow weir, the inlet and outlet sizes, and the overflow outlet size. The control of overflow fineness requires adjustments to the height of the overflow weir, the size of the overflow outlet, the amount and ratio of steel balls, grinding concentration, and overflow concentration.

In summary, all technical parameters in the grinding operation are interrelated, complementary, and mutually restrictive. Therefore, a comprehensive and coordinated approach must be taken during the adjustment and control process.

Preventing the hydrolysis of cyanides is very important.

The Cyanides we commonly use (potassium cyanide, Sodium cyanide, calcium cyanide) are all strong bases and weak acid salts, which are prone to hydrolysis in water, generating hydrogen cyanide that can affect the concentration of cyanide ions in the pulp. Therefore, it is crucial to prevent the hydrolysis of cyanides during the leaching process. The most effective method is to increase the concentration of hydroxide ions, which is what we typically refer to as increasing the pH value. The most economical pH adjustment agent in industry is lime, but lime can also easily cause flocculation while adjusting the pH. Therefore, we add it during the grinding operation to ensure it is well dispersed.During cyanide leaching, the solution must maintain a certain alkalinity to prevent the decomposition of cyanides, but the alkalinity of the cyanide solution should not be too high, as this can reduce the dissolution rate of gold.

As the leaching time increases, the gold leaching rate improves, but after a certain point, extending the leaching time further does not significantly increase the gold leaching rate. Therefore, it is essential to ensure a certain leaching time during cyanide leaching to guarantee effective gold leaching.Generally, the pH value during carbon pulp operations is most effective when it is between 10 and 11.

Controlling the pulp concentration is a key aspect of the cyanidation process.

Whether it is gold and cyanide or gold cyanide and activated carbon, sufficient contact is necessary to achieve good mineral processing indicators, which places high demands on the pulp concentration. If the concentration is too high, it can easily precipitate on the surface of the activated carbon; if it is too low, it can easily settle. Additionally, to maintain an appropriate pH value and cyanide concentration, a large amount of reagents must be added. When selecting cyanides, factors such as their relative ability to dissolve gold, stability, and the impact of impurities on gold dissolution must be considered.

After years of production practice, it is believed that a concentration of 40-45% for carbon pulp gold extraction and a cyanide concentration of 300-500 ppm are more suitable. However, as mentioned earlier, grinding typically requires two to three stages of operation, and the final product concentration is generally below 20%. Therefore, prior to entering the leaching operation, the pulp must undergo a thickening process.

The control of Sodium Cyanide concentration during the leaching operation should follow these principles: while ensuring gold dissolution efficiency, appropriately reduce the sodium cyanide concentration to make the sodium cyanide concentration consistent across all series leaching tanks, or ensure that the sodium cyanide concentration in the earlier leaching tanks is higher than in the later ones. The smaller the fluctuation range of sodium cyanide concentration controlled in each leaching tank, the better. It is preferable for the ratio of leaching tanks that add sodium cyanide to the total number of leaching tanks to be higher. Measuring the sodium hydroxide concentration more frequently is beneficial for controlling operational technical conditions. Sodium cyanide is generally added to each tank at a concentration of around 10%.

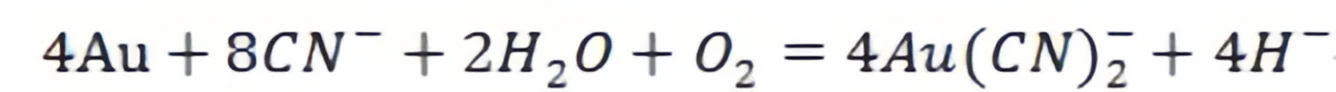

The Basic Mechanism of the Cyanide Leaching Process

From the above formula, it can be seen that the cyanidation process is an oxygen-requiring process, as the introduction of oxygen during production can accelerate the leaching rate. Of course, we can also appropriately add oxidizing agents, such as hydrogen peroxide; however, excessive oxidants can lead to the formation of cyanate ions from cyanide, which is not beneficial for the leaching process.

From the formula, we can also see that 1 mol of gold requires only 2 mol of cyanide for complexation. In terms of mass, approximately 1 g of gold requires 0.5 g of cyanide as a leaching agent. However, in actual production, due to the influence of other minerals, such as silver, copper, lead, and zinc, which can also undergo complexation reactions with cyanide, the dosage of reagents should not be limited to calculations alone. It should be adjusted based on the final leaching rate, and adjustments should be tracked when the ore properties change. Typically, a range of 200 to 500 times higher than the calculated value is considered reasonable. In summary, ensuring the concentration of cyanide ions in the pulp is a necessary condition for achieving good indicators.

When the gold adsorbed on the loaded carbon reaches over 3000 g/t, we consider that the entire carbon pulp adsorption process is complete. However, ores with high impurities of copper and silver can also affect the adsorption capacity of activated carbon, resulting in the gold-loaded carbon not meeting our expected targets. When the activated carbon no longer has adsorption capacity, we consider it to be saturated. For saturated activated carbon, we need to desorb and electrolyze to obtain gold. However, the subsequent operations are more complex and require a larger investment. In regions with high gold production density, we can sell the gold-loaded carbon for profit, or a simpler method is to obtain gold by burning.

Shaanxi United Chemical is a professional manufacturer and supplier of sodium cyanide, a key chemical used in various industries such as mining and chemical synthesis. The professional team at United Chemical not only provides products but is also dedicated to offering comprehensive technical support. With extensive industry experience, our experts are capable of addressing any questions or challenges you may encounter. By choosing Shaanxi United Chemical as your sodium cyanide supplier, you will gain access to a wealth of knowledge and resources that can enhance your operations and improve efficiency. Partner with us now to experience professional technical support and high-quality products.

- Random Content

- Hot content

- Hot review content

- High Quality Sodium silicate 99% Water glass

- အလုပ် ခေါင်းစဉ် : ပြောင်းသာလဲသာ ရှိ သော ဖောက်သည် နှင့် ထောက်ပံ့ ပေး သူ ဆက်ဆံရေး ကျွမ်းကျင် သူMyanmar

- Industrial Grade Sodium Metabisulfite 96.5%

- IPETC 95%Metal sulfide mineral collector Z-200

- Sodium bisulfite 99% High Quality Factory Supply

- Thiourea 99% high activity Professional Producer

- Manganese sulfate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: