Introduction

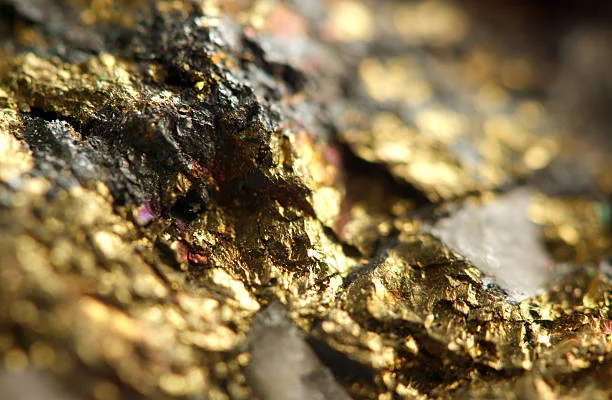

Cyanide leaching is a widely used method for extracting gold from gold ore. Among the various factors influencing the cyanide leaching process, the leaching time of sodium cyanide plays a crucial role in determining the recovery rate of gold. Understanding the relationship between them is essential for optimizing the cyanide leaching operation and improving the economic efficiency of gold production.

The Process of Cyanide Leaching

In the cyanide leaching process, gold in the ore reacts with Sodium Cyanide in the presence of oxygen to form soluble gold cyanide complexes. The chemical reaction can be simply expressed as: 4Au + 8NaCN + O₂ + 2H₂O = 4Na[Au(CN)₂] + 4NaOH. This reaction occurs on the surface of gold particles, and the rate and extent of the reaction are affected by multiple factors, with leaching time being one of the significant ones.

How Leaching Time Affects Recovery Rate

Initial Stage

At the beginning of the leaching process, as time progresses, the amount of gold dissolved into the solution increases rapidly. Gold particles on the surface of the ore are quickly attacked by cyanide ions. The fresh surface of gold provides a large number of reaction sites, and the concentration gradient between the surface of gold particles and the solution promotes the continuous dissolution of gold. During this period, the leaching rate of gold shows a steep upward trend, and the recovery rate increases significantly with the extension of leaching time.

Middle Stage

As the leaching continues, the gold on the outer surface of the ore particles is gradually dissolved, and the remaining gold particles are either deeper inside the ore particles or have a more complex embedding state. At this time, the leaching rate begins to slow down. Although the reaction is still proceeding, the diffusion of cyanide ions to the surface of gold particles becomes more difficult due to the formation of a saturated solution layer around the particles and the obstruction of some reaction products. However, the recovery rate still increases, but at a relatively slower pace compared to the initial stage.

Later Stage

After a certain long leaching time, the leaching rate of gold approaches a constant value. Most of the easily accessible gold has been dissolved, and the remaining gold is either in a very fine-grained state, tightly wrapped by other minerals, or exists in a form that is difficult to react with cyanide. Prolonging the leaching time at this stage has little impact on increasing the recovery rate. In fact, continuing to extend the leaching time may even cause some negative effects, such as increased consumption of Sodium cyanide, energy consumption for equipment operation, and potential environmental pollution risks due to the longer exposure of cyanide-containing solutions.

Case Studies

Case 1: A Gold Mine in Shandong, China

In a gold mine in Shandong, researchers conducted a series of experiments on cyanide leaching. They found that when the leaching time was 12 hours, the gold recovery rate was only 60%. As the leaching time was extended to 24 hours, the recovery rate increased to 80%. However, when the leaching time was further extended to 36 hours, the recovery rate only increased slightly to 82%. This shows that within a certain range, extending the leaching time can effectively improve the recovery rate, but after reaching a certain point, the marginal effect of increasing the recovery rate by extending the leaching time becomes negligible.

Case 2: An Australian Gold Mine

In an Australian gold mine, different leaching time conditions were set for different batches of ore. For ore with a relatively simple composition, when the leaching time was 18 hours, a recovery rate of 85% was achieved. But for ore with a more complex composition containing more impurities, even after 36 hours of leaching, the recovery rate only reached 75%. This indicates that the impact of leaching time on the recovery rate is also related to the nature of the ore. Ores with complex compositions may require longer leaching times to achieve satisfactory recovery rates, but there is also a limit.

Optimization of Leaching Time

To optimize the leaching time, several aspects need to be considered comprehensively. First, it is necessary to conduct detailed mineralogical analysis of the ore to understand the occurrence state of gold, such as the particle size of gold, the degree of embedding, and the content of associated minerals. Based on this, an appropriate initial leaching time can be estimated. Second, during the leaching process, real-time monitoring of the concentration of gold in the leaching solution and the remaining gold content in the ore can be carried out through sampling and analysis. According to the change trend of these data, the leaching time can be adjusted in a timely manner. Third, in combination with other factors affecting the leaching process, such as the concentration of sodium cyanide, the pH value of the solution, and the temperature, a comprehensive optimization plan can be formulated to achieve the best balance between the recovery rate and production costs.

Conclusion

The leaching time of sodium cyanide has a significant impact on the recovery rate of gold in the cyanide leaching process. In the initial and middle stages of leaching, extending the leaching time can effectively increase the recovery rate. However, after reaching a certain stage, further extending the leaching time has little effect on improving the recovery rate and may bring some negative impacts. Different types of ores have different optimal leaching times, which need to be determined through comprehensive consideration of various factors and actual experiments. By optimizing the leaching time, the efficiency of gold cyanide leaching can be improved, and better economic and environmental benefits can be achieved in the gold mining industry.

- Random Content

- Hot content

- Hot review content

- The Essential Guide to Sodium Cyanide: Usage Cases and Sourcing

- Sodium bisulfite 99% High Quality Factory Supply

- Calcium Peroxide 60% Assay Yellowish Tablet

- Sodium Persulfate,Sodium Persulphate,supplier 99.00%

- Antimonium Tartrate Potassium

- Barium carbonate 99% powder

- Lithium hydroxide 99% Solid

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: