Introduction

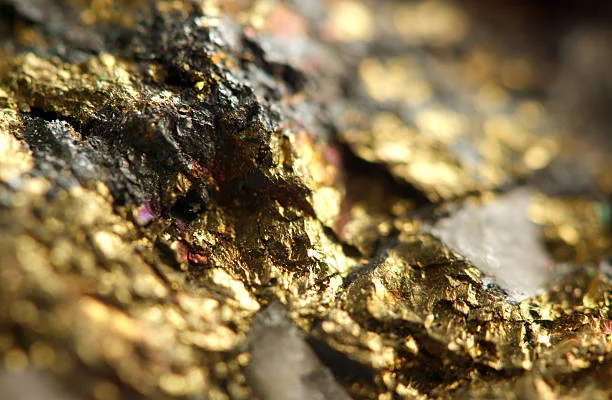

Cyanidation leaching is a widely used process in the mining industry for extracting gold and silver from ore. In this process, Sodium cyanide and Protective alkali play crucial roles. Understanding their functions is essential for optimizing the cyanidation process, improving metal recovery rates, and reducing operational costs.

The Role of Sodium Cyanide

Dissolving Gold and Silver

Sodium cyanide (NaCN) serves as the primary leaching agent in the cyanidation process. Its core function is to dissolve gold and silver within the ore, resulting in the formation of soluble metal cyanide complexes. In the presence of oxygen and water, Sodium Cyanide reacts with gold and silver. This reaction converts the metals into compounds that can easily dissolve in the aqueous solution, which is fundamental to the Cyanidation leaching process.

Affecting the Leaching Rate

The concentration of sodium cyanide in the leaching solution significantly impacts the leaching rate of gold and silver. Typically, within a specific range, an increase in sodium cyanide concentration accelerates the leaching rate. More cyanide ions mean more reactants available for the dissolution reaction, thus promoting the formation of metal cyanide complexes. However, overly high sodium cyanide concentrations lead to increased costs and potential environmental hazards. Additionally, excessive cyanide can react with other components in the ore, such as certain metal sulfides. These reactions consume cyanide, reducing its effectiveness for dissolving gold and silver.

Reacting with Other Components in the Ore

Ore contains various impurities and components besides gold and silver, and sodium cyanide can interact with these substances, affecting the cyanidation process. For example, copper minerals in the ore react with sodium cyanide to form copper cyanide complexes, consuming cyanide in the process. The reactions with different copper minerals vary in rate and products. Some copper sulfide minerals, like chalcopyrite, react with cyanide in the presence of oxygen, producing copper cyanide and sulfur - containing by - products. This not only decreases the amount of cyanide available for dissolving gold and silver but may also generate substances that interfere with subsequent metal recovery processes.

The Role of Protective Alkali

Maintaining the Stability of Cyanide Solution

One of the key functions of protective alkali is to maintain the stability of the cyanide solution. Cyanide ions in solution are prone to hydrolysis, especially in acidic environments. During hydrolysis, cyanide ions can form hydrogen cyanide, a highly toxic and volatile gas. This not only causes the loss of cyanide but also poses severe threats to the environment and human health. Protective alkalis, such as calcium hydroxide (lime), sodium hydroxide, or potassium hydroxide, increase the pH value of the solution. By raising the pH, they shift the chemical equilibrium in a way that reduces the hydrolysis of cyanide, ensuring the effectiveness of the cyanidation process and minimizing cyanide consumption due to hydrolysis.

Reducing the Impact of Harmful Minerals

Ore may contain minerals that are detrimental to the cyanidation process, like pyrrhotite. These minerals react with cyanide and oxygen, consuming these crucial substances and interfering with the dissolution of gold and silver. When protective alkali is added during the ore grinding process, it can oxidize these harmful minerals or cause them to form precipitates, effectively removing them. For instance, in the presence of lime, pyrrhotite can be oxidized, resulting in the formation of iron hydroxide precipitates and sulfur - containing compounds. This process mitigates the negative impact of harmful minerals on cyanidation, enhancing the leaching efficiency of gold and silver.

Adjusting the pH Value of the Pulp

The pH value of the pulp during the cyanidation process is a critical parameter, and protective alkali is used to adjust it to an optimal range. For most cyanidation processes, a pH between 9 and 12 is generally ideal. Within this range, the cyanide solution remains stable, and the dissolution of gold and silver proceeds smoothly. If the pH is too low, cyanide hydrolysis becomes significant, decreasing the leaching rate of gold and silver. Conversely, a pH that is too high can negatively affect the surface properties of the ore particles and the reaction kinetics of gold and silver dissolution. Different types of protective alkalis can be selected based on the specific characteristics of the ore. Lime is commonly used due to its low cost and good performance in most scenarios. When using lime as a protective alkali, it is often added in the form of lime milk for better control of the addition amount and reaction process.

Interaction between Sodium Cyanide and Protective Alkali

The functions of sodium cyanide and protective alkali are closely intertwined in the cyanidation leaching process. Protective alkali ensures the stability of the sodium cyanide solution, enabling it to effectively dissolve gold and silver. At the same time, the presence of sodium cyanide in the solution influences the effectiveness of the protective alkali. The reaction products of sodium cyanide with other ore components can change the solution's pH, and the protective alkali must continuously adjust the pH to maintain optimal cyanidation conditions. The appropriate ratio of sodium cyanide and protective alkali is crucial. Excessive protective alkali can lead to overly high alkalinity, negatively impacting the cyanidation reaction. Insufficient protective alkali, on the other hand, fails to guarantee the stability of the cyanide solution, resulting in increased cyanide consumption and reduced leaching efficiency. Therefore, in actual cyanidation process operations, it is necessary to carefully control the dosages of sodium cyanide and protective alkali according to the ore characteristics and process requirements to achieve the best leaching results.

Conclusion

In the cyanidation leaching process, sodium cyanide and protective alkali are both essential components. Sodium cyanide is responsible for dissolving gold and silver, while protective alkali plays a vital role in maintaining the stability of the cyanide solution, reducing the impact of harmful minerals, and adjusting the pH value of the pulp. The proper use and balance of these two substances are crucial for optimizing the cyanidation process, improving the recovery rate of gold and silver, and reducing production costs. Mining operators need to carefully study the characteristics of the ore and conduct appropriate tests to determine the optimal dosages and operating conditions of sodium cyanide and protective alkali to ensure the efficient and sustainable operation of the cyanidation leaching process.

- Random Content

- Hot content

- Hot review content

- Flexible Customer and Supplier Relations Specialist:Location: Laos

- Food Grade Heavy Light Precipitated Calcium Carbonate Powder Granular 99%

- Dodecylbenzenesulfonic acid

- Triethanolamine(TEA)

- lithium Carbonates 99.5% Battery Level or 99.2% Industry grade 99%

- Pharmaceutical Intermediate Glycine with High Quality 99%

- 99.9% Purity Ethyl Acetate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: