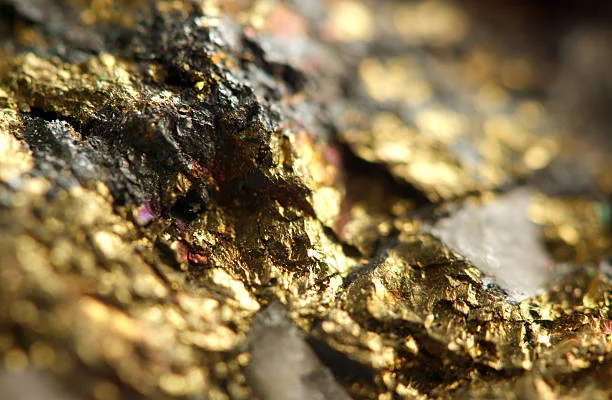

Introduction

Cyanide leaching is a widely used process in the extraction of gold and silver from ore. However, the presence of various Associated Minerals in the ore can significantly influence the efficiency and effectiveness of this process. Understanding these impacts is crucial for optimizing cyanide leaching operations and improving the recovery of valuable metals.

Iron Minerals

Pyrite

Pyrite is a common iron - sulfide mineral in gold - bearing ores. During cyanide leaching, when pyrite is in the pulp, it can be oxidized to form ferrous sulfate. This ferrous sulfate then reacts with cyanide to create ferrocyanate. This reaction consumes a large amount of Sodium Cyanide, which is a key reagent for gold leaching. Moreover, with the action of lime and air, pyrite can also transform into soluble sulfide, colloidal sulfur, or thiosulfate. This transformation process uses up oxygen, which is essential for the dissolution of gold in the cyanide - leaching system. Overall, this has a negative impact on the gold - leaching efficiency.

Pyrrhotite

Pyrrhotite is another iron - sulfide mineral that affects cyanide leaching. It easily reacts with cyanide to produce thiocyanate. Additionally, the ferrous sulfate formed from its oxidation also reacts with cyanide to form ferrocyanate. Research has shown that pyrrhotite can cause a significant decrease in the gold - dissolution rate, for example, reducing it by 28.1% in some cases. It also leads to a substantial increase in cyanide consumption, often quadrupling it.

Copper Minerals

Chalcopyrite and Chalcocite

Copper minerals such as chalcopyrite and chalcocite have a notable impact on cyanide leaching. Cyanide solution can dissolve copper minerals, but the dissolution rate varies. Chalcopyrite is relatively stable among copper sulfide minerals, while chalcocite is more reactive. In cyanide solution, the copper in these minerals, usually in the divalent state, is unstable. Divalent copper oxidizes cyanide, changing to monovalent copper and forming complexes with cyanide in the pulp. For chalcocite, it can cause a significant decline in the gold - dissolution rate, up to 36.81% in some experiments, and a ten - fold increase in cyanide consumption.

Malachite (Copper Oxide Mineral)

Malachite is a common copper - oxide mineral. It dissolves easily in sodium - cyanide solution, which leads to a significant increase in cyanide consumption. The reaction between malachite and cyanide uses up a large number of cyanide ions. As a result, both copper sulfide and copper oxide minerals can have a substantial negative impact on the cyanide - gold - extraction process.

Arsenic Minerals

Realgar and Orpiment

Realgar and orpiment are highly harmful to cyanide leaching. In the strongly alkaline solution used for cyanide immersion, they form compounds such as thioarsenite. Thioarsenite can react with the oxygen in the solution to form arsenite, consuming a large amount of oxygen in the mineral slurry. Also, when arsenic minerals are oxidized in the solution, a film made of arsenic compounds forms on the surface of gold particles. This film directly stops gold from coming into contact with cyanide, severely affecting the dissolution of gold. Studies have indicated that realgar and orpiment can reduce the gold - dissolution rate by 41.95% and 49.90% respectively, and increase cyanide consumption by 13.8 times and 15.0 times.

Arsenopyrite

Arsenopyrite is a common arsenic - containing mineral. Unlike realgar and orpiment, arsenopyrite is relatively stable in the cyanide system. Although it contains arsenic, under normal cyanide - leaching conditions, it does not break down easily and thus has a relatively minor impact on cyanide leaching compared to other arsenic - bearing minerals.

Lead Minerals

Galena and Lead Alum

Galena and lead alum are the main lead - containing minerals in gold mines. Galena can be oxidized to lead alum. In a strong - alkaline solution, lead alum can produce alkaline lead - acid salt, which reacts with the cyanide in the solution to form insoluble strong - alkaline cyanide. A small amount of lead minerals can actually help the cyanide leaching of gold mines. However, a large quantity of lead minerals will affect the gold - leaching efficiency by consuming cyanide and possibly forming precipitates that can interfere with the leaching process.

Antimony - Containing Minerals

Stibnite

Stibnite is the main antimony - containing sulfide mineral. In the cyanide - leaching process, its negative effects are similar to those of orpiment. It easily dissolves in a strong - alkaline solution to produce thioantimonite, which is then further oxidized into antimonite. Additionally, negatively charged stibnite colloidal particles in the alkaline - cyanide solution can stick to the surface of gold particles, physically preventing gold from dissolving.

Carbon Substances

Gold mines may contain carbon substances, including inorganic carbon and organic carbon like humic acid. When these carbon substances are present, they can absorb the dissolved gold in the cyanide solution. This reduces the leaching rate of gold in the solution, a phenomenon known as “gold robbery.” The carbon substances compete with the extraction process for the dissolved gold, leading to a loss of gold recovery.

Strategies to Mitigate the Impact of Associated Minerals

Pretreatment of Ores

Oxidation Pretreatment: For ores with iron - sulfide, arsenic, or antimony minerals, oxidation pretreatment can be effective. Oxidation breaks down these minerals, freeing the enclosed gold and reducing their harmful effects on cyanide leaching. Common oxidation - pretreatment methods include roasting, pressure oxidation, and bio - oxidation.

Copper - Pre - leaching: In the case of ores with high copper content, pre - leaching for copper can be done. By removing copper before cyanide leaching, the amount of cyanide consumed by copper minerals can be minimized, thus improving the efficiency of gold cyanide leaching.

Optimization of Cyanide - Leaching Conditions

Adjusting Reagent Dosages: Based on the type and amount of associated minerals, the amount of cyanide and other reagents can be adjusted. For example, when there are a lot of copper minerals, increasing the cyanide dosage a bit while controlling the pH value can help ensure gold dissolves effectively.

Controlling Pulp Conditions: Controlling the pulp concentration, temperature, and stirring speed is also important. The right pulp concentration ensures that cyanide and oxygen can spread efficiently in the pulp. Keeping an appropriate temperature (usually 15 - 30 °C) balances the speed at which gold dissolves and the stability of the cyanide solution.

Use of Additives

Additives to Inhibit Mineral Reactions: Additives like lead salts can be used to stop certain harmful minerals from reacting. For example, adding lead acetate can react with sulfide ions from the breakdown of sulfur - containing minerals, forming insoluble lead - sulfide precipitates. This reduces the amount of cyanide and oxygen that sulfur - containing minerals consume.

Competitive Adsorbents: In the case of ores with carbon substances, adding competitive adsorbents such as activated carbon during cyanide leaching can reduce the “gold - robbery” effect. Activated carbon competes with the carbon in the ore for dissolved gold, thereby increasing the gold - leaching rate.

Conclusion

The associated minerals in gold and silver ores have diverse and significant impacts on the cyanide - leaching process. Iron, copper, arsenic, lead, antimony - containing minerals, and carbon substances can all affect the leaching efficiency by consuming reagents, preventing gold from contacting cyanide, or absorbing dissolved gold. However, through appropriate pretreatment methods, optimization of leaching conditions, and the use of additives, these negative impacts can be reduced. This enables more efficient extraction of gold and silver from complex - mineralized ores, improving the economic viability of mining operations.

- Random Content

- Hot content

- Hot review content

- Polyethylene Glycol PEG - 2000/4000/6000/8000 alcohol ethoxylate surfactant

- Industrial concentrated nitric acid 55%-68%

- High-strength Shock tube(VOD≧2000m/s)

- Potassium Permanganate – Industrial Grade

- Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- Pharmaceutical Grade Zinc Acetate

- butyl vinyl ether

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: