1. Introduction

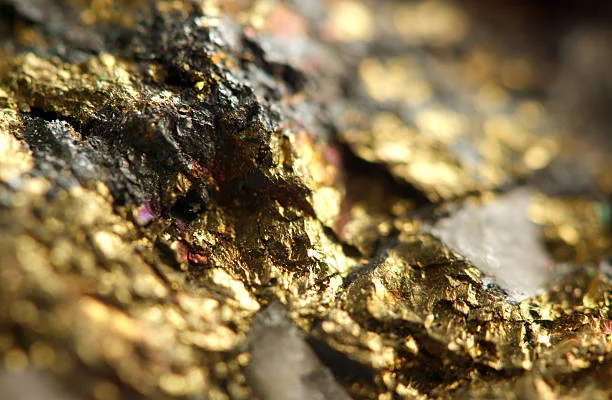

Cyanidation is a widely used process in the extraction of gold from ores. Among its various operational modes, atmospheric leaching and pressure leaching are two important methods. Understanding the differences between them is crucial for optimizing the gold extraction process, improving efficiency, and reducing costs. This article will conduct a detailed comparison between atmospheric and pressure leaching in the gold mine cyanidation process.

2. Principle of Cyanidation Leaching

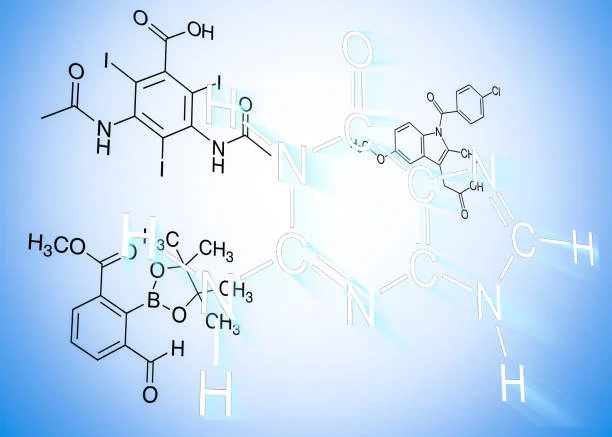

Cyanidation leaching is based on the reaction of gold with cyanide in the presence of oxygen. The general chemical equation is as follows:

4Au + 8CN⁻+ O₂ + 2H₂O → 4[Au(CN)₂]⁻+ 4OH⁻

In this reaction, gold forms soluble gold - cyanide complexes, which can be further separated and recovered. Whether in atmospheric or pressure leaching, this basic reaction principle remains the same. However, the reaction conditions and kinetics are affected by the pressure factor.

3. Comparison of Leaching Efficiency

3.1 Atmospheric Leaching

Atmospheric leaching usually operates at ambient temperature and pressure. For some relatively simple gold ores, such as those with a high proportion of free - milling gold, atmospheric leaching can achieve good results. However, for complex ores containing a large amount of sulfide minerals or other refractory components, the leaching efficiency of atmospheric leaching is often limited. The slow reaction rate and incomplete reaction may lead to a lower gold leaching rate. For example, when dealing with gold ores containing pyrite, the sulfur in pyrite may react with oxygen and cyanide during atmospheric leaching, consuming oxygen and cyanide, and thus inhibiting the dissolution of gold. In general, the gold leaching rate in atmospheric leaching is around 60% - 85% for common ores.

3.2 Pressure Leaching

Pressure leaching, on the other hand, is carried out under elevated pressure conditions. The increase in pressure can significantly increase the solubility of oxygen in the leaching solution. According to Henry's law, higher pressure leads to a higher partial pressure of oxygen, which in turn increases the concentration of dissolved oxygen in the solution. This high - concentration dissolved oxygen can accelerate the oxidation of gold and the formation of gold - cyanide complexes. For refractory gold ores, pressure leaching can break down the refractory structures of sulfide minerals, exposing more gold to the leaching solution. As a result, the leaching rate of gold can be effectively improved. Research shows that for some refractory gold ores, the gold leaching rate of pressure leaching can reach over 90%, even up to 95% under optimized conditions.

4. Comparison of Reaction Conditions

4.1 Temperature

Atmospheric Leaching: Usually operates at or near ambient temperature, typically around 25°C. Since the reaction is not driven by high temperature, the energy consumption for heating is relatively low. However, the low temperature also means that the reaction rate is relatively slow.

Pressure Leaching: Generally requires an elevated temperature. The temperature is usually in the range of 80 - 150°C. Higher temperature can accelerate the chemical reaction rate, but it also requires additional energy input for heating the leaching system.

4.2 Cyanide Concentration

Atmospheric Leaching: The concentration of cyanide in the leaching solution is usually in the range of 0.02% - 0.1%. For ores with high impurity content, a relatively higher cyanide concentration may be required to ensure the leaching effect, but this will increase the cost and environmental risk.

Pressure Leaching: Due to the enhanced reaction kinetics under pressure, the required cyanide concentration can be relatively lower, generally around 0.01% - 0.05%. This not only reduces the consumption of cyanide but also decreases the environmental impact caused by cyanide residues.

5. Comparison of Equipment Requirements and Costs

5.1 Equipment Requirements

Atmospheric Leaching: The equipment for atmospheric leaching is relatively simple. It mainly includes leaching tanks, agitators, and aeration devices. The leaching tanks do not need to withstand high pressure, so their manufacturing materials and costs are relatively low. Agitators are used to ensure the uniform mixing of the ore pulp, cyanide solution, and oxygen, and the requirements for their power and corrosion resistance are not extremely high.

Pressure Leaching: Pressure leaching requires special pressure - resistant equipment, such as autoclaves. The autoclave needs to be made of high - strength alloy materials to withstand high pressure and high - temperature environments. In addition, it is also equipped with complex pressure control, temperature control, and safety protection systems. The design and manufacturing of these equipment are more complex and require higher technical levels.

5.2 Costs

Atmospheric Leaching: The initial investment cost for atmospheric leaching equipment is relatively low. However, due to its relatively low leaching efficiency and long leaching time, the operating cost in terms of labor, power consumption for long - time agitation, and cyanide consumption may be relatively high in the long run.

Pressure Leaching: The initial investment in pressure leaching equipment is much higher because of the expensive pressure - resistant autoclaves and complex control systems. But considering its high leaching efficiency and short leaching time, the overall operating cost in terms of production capacity and resource utilization may be more competitive for large - scale and refractory ore processing.

6. Environmental Impact

6.1 Cyanide Residue

Atmospheric Leaching: As mentioned before, atmospheric leaching may require a relatively higher concentration of cyanide, which may lead to more cyanide residues in the tailings. Cyanide is highly toxic, and improper treatment of cyanide - containing tailings can pose a serious threat to the environment and human health.

Pressure Leaching: With a lower cyanide consumption, pressure leaching generates relatively less cyanide residue in the tailings. This reduces the environmental risk associated with cyanide pollution to a certain extent.

6.2 Energy Consumption and Emissions

Atmospheric Leaching: Although it has a low energy consumption for heating, the long - time operation for achieving satisfactory leaching results may consume a large amount of electrical energy for agitation and aeration. In terms of emissions, if the aeration process is not well - controlled, it may cause the release of some harmful gases generated by the reaction.

Pressure Leaching: The high - temperature and high - pressure operation of pressure leaching require significant energy input for heating and maintaining the pressure system. However, its high - efficiency operation means that for the same amount of gold production, the overall energy consumption per unit of gold may be comparable or even lower than that of atmospheric leaching considering the higher production capacity. In terms of emissions, if the pressure system is well - sealed, the release of harmful gases can be better controlled.

7. Conclusion

In summary, both atmospheric and pressure leaching in the gold mine cyanidation process have their own characteristics. Atmospheric leaching is suitable for simple gold ores with low investment in equipment initially, but it has limitations in leaching efficiency for complex ores. Pressure leaching, on the contrary, shows great advantages in dealing with refractory gold ores, with high leaching efficiency, lower cyanide consumption, and relatively less environmental impact in terms of cyanide residues. However, it requires high - cost equipment and more complex operation and maintenance. When choosing a leaching method, mining enterprises need to comprehensively consider factors such as ore properties, production scale, investment budget, and environmental requirements to make the most appropriate decision.

- Random Content

- Hot content

- Hot review content

- China factory Sulfuric Acid 98%

- butyl vinyl ether

- 97% 2-Hydroxypropyl methacrylate

- 99.9% Purity Ethyl Acetate

- Fuel Additive Octane Value Booster Ferrocene

- How do I assess the economic viability and effectiveness of mining chemicals?

- Ferrochrome lignosulfonate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: