1. Introduction

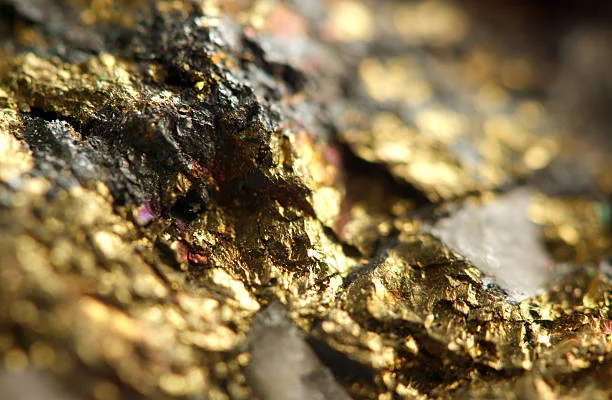

The Cyanidation vat leaching method is an important process in gold mining for extracting gold from ores. This method has its specific applicable scope and a series of well - defined process steps, which play a crucial role in the efficient extraction of gold resources.

2. Applicable Scope

2.1 Ore Particle Size Requirement

Gold ores suitable for the vat leaching method typically have fine - grained gold dissemination. When the gold particles in the ore are very fine, it is difficult to separate them through simple physical separation methods such as gravity separation. In such cases, the cyanidation vat leaching method can be used. For example, in some oxide - type gold ores, the gold often exists in the form of fine grains, which can be effectively treated by vat leaching.

2.2 Ore Grade Requirement

This method is particularly suitable for low - grade or ultra - low - grade gold ores. For high - grade gold ores, more efficient and less time - consuming extraction methods may be preferred. However, for low - grade ores where the gold content per unit mass of ore is relatively low, the vat leaching method can still achieve economic extraction under certain conditions. The relatively low cost of the vat leaching process makes it a viable option for processing such ores.

2.3 Ore Permeability Requirement

Ores with poor permeability are also suitable for vat leaching. If the ore has good permeability, the cyanide solution may flow through the ore too quickly, resulting in insufficient contact time between the cyanide and the gold, and thus reducing the gold leaching rate. In contrast, for ores with poor permeability, the vat leaching method can control the flow rate and contact time of the cyanide solution in the ore to ensure better leaching results. For instance, iron oxide - capping - type ores containing fine - grained gold and oxidized quartz - vein - type ores with fine - grained gold often have relatively poor permeability and are quite suitable for vat leaching. The vat leaching method can achieve a beneficiation recovery rate of 70 - 90% for such ores.

3. Process Flow

3.1 Preparation of Leaching Vats

The leaching vats used in the processare usually made of materials such as wood, iron, or concrete. The bottom of the vat can be flat or slightly inclined, and the shape can be circular, rectangular, or square. Inside the vat, a false bottom made of perforated acid - resistant plates is installed. A filter cloth is laid on the false bottom, and a grid made of wooden strips or corrosion - resistant metal strips is covered on the filter cloth. The false bottom is used to filter and support the ore. Before starting the leaching process, it is necessary to ensure that the vats, especially the leaching vat and the poor - liquid vat, are impermeable and basically dry.

3.2 Ore Pretreatment - Crushing and Screening

The mined gold - bearing ores need to be crushed to a certain particle size. Firstly, the ores are fed into the crushing stage for simple dissociation. Depending on the required ore particle size, there are coarse - crushing, medium - crushing, and fine - crushing operations. Usually, a jaw crusher is used for coarse - crushing, which can reduce the particle size to about 50 - 100mm. Then, a cone crusher is used for medium - crushing and fine - crushing operations, reducing the particle size to the range of 5 - 25mm. After crushing, the ores are screened by a vibrating screen to ensure a uniform particle size. Coarse - grained ores that do not meet the requirements are returned to the crusher for re - crushing, and the qualified - sized ores enter the next step.

3.3 Leaching Process

Loading Ores into the Vat: The crushed and screened ores are loaded into the leaching vat.

Preparing the Leaching Solution: In the poor - liquid vat, an alkaline cyanide solution is prepared as the leaching agent. The concentration of the cyanide solution is usually controlled within a certain range, generally 0.05% - 0.1%, which is determined through experiments according to the specific ore properties. This concentration can ensure efficient gold extraction while minimizing environmental impact.

Leaching Operation: The prepared leaching solution is pumped into the leaching vat. During the leaching process, the leaching solution slowly permeates through the ore layer. The gold in the ore reacts with the cyanide in the solution under the action of oxygen (usually, air is introduced into the vat). The main chemical reaction equation is: \(4Au + 8NaCN+O_2 + 2H_2O = 4Na[Au(CN)_2]+4NaOH\). In this reaction, gold forms soluble gold - cyanide complexes and dissolves into the solution. The leaching time is relatively long, usually ranging from several days to several weeks, depending on factors such as the nature of the ore, the particle size of the ore, and the concentration of the leaching solution. During the leaching process, it is necessary to regularly detect the concentration of the leaching solution, the pH value of the solution, and the gold content in the solution to ensure that the leaching reaction proceeds under optimal conditions.

3.4 Separation of Gold - Bearing Solution (Rich - Liquid)

When the leaching reaches a certain time and through detection, when the concentration and grade of the liquid meet the requirements, the gold - bearing solution (rich - liquid) is discharged from the bottom of the vat. The rich - liquid contains dissolved gold - cyanide complexes and needs to be further processed to recover gold.

3.5 Gold Recovery

Zinc Powder (Sheet) Displacement Method: One common method for Gold recovery is the zinc powder (sheet) displacement method. Zinc has a stronger reducing property than gold. When zinc powder or zinc sheet is added to the rich - liquid, a displacement reaction occurs. The chemical reaction equation is: \(2Na[Au(CN)_2]+Zn = 2Au+Na_2[Zn(CN)_4]\). Gold is displaced from the gold - cyanide complex by zinc and precipitates in the form of solid particles. After the displacement reaction, the solid - liquid mixture is filtered to obtain gold - containing solids, which are then further processed for smelting.

Activated Carbon Adsorption Method: Another method is activated carbon adsorption. Activated carbon has a large specific surface area and strong adsorption capacity. The rich - liquid is passed through a column filled with activated carbon. The gold - cyanide complexes in the solution are adsorbed onto the surface of the activated carbon. After adsorption, the activated carbon with adsorbed gold (loaded - carbon) is separated from the solution. Then, the loaded - carbon is subjected to desorption treatment. Usually, a desorption solution (such as a mixture of sodium hydroxide and Sodium Cyanide) is used to desorb the gold from the activated carbon at a certain temperature and pressure. The desorbed gold - containing solution is then electrolyzed to obtain gold.

3.6 Treatment of Tailings and Waste Liquids

Tailings Treatment: After gold recovery, the remaining tailings still contain a certain amount of cyanide and other impurities. In order to meet environmental protection requirements, the tailings need to be treated. One common method is to add reagents such as sodium metabisulfite and copper sulfate to the tailings to decompose and remove cyanide. After treatment, the tailings can be properly stored or further processed.

Waste - Liquid Treatment: The waste - liquid generated during the process also contains cyanide and other harmful substances. It needs to be treated through processes such as chemical precipitation, ion exchange, and biological treatment to reduce the content of harmful substances to meet the national discharge standards before being discharged.

4. Conclusion

The cyanidation vat leaching method has its unique applicable scope in the gold mining industry, especially for fine - grained, low - grade, and low - permeability gold ores. Through a series of strict process steps, this method can effectively extract gold from ores. However, it should be noted that due to the use of cyanide in the process, strict safety and environmental protection measures must be taken to ensure the safety of workers and minimize the impact on the environment. With the continuous development of mining technology, further improvements and optimizations of this process are expected to improve gold extraction efficiency and reduce costs while ensuring environmental friendliness.

- Random Content

- Hot content

- Hot review content

- Ammonium Nitrate Porous Prills

- Thiourea 99% high activity Professional Producer

- Potassium borohydride

- Toluene

- Manganese sulfate

- Lithium hydroxide 99% Solid

- Ammonium Bisulfite 70% Solution

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: