Sodium cyanide is an important basic chemical raw material, widely used in many industries such as mining, electroplating, and chemical manufacturing. However, due to its extremely high toxicity, any leakage or improper handling during Transportation can pose a serious threat to human health and the environment. Therefore, the transportation of Sodium Cyanide must comply with strict requirements.

1. Regulatory Compliance

1.1 Legal Framework

In most countries, the transportation of sodium cyanide is strictly regulated by relevant laws and regulations. For example, in the United States, the Department of Transportation (DOT) has detailed regulations in the Code of Federal Regulations (CFR), Title 49. These regulations cover aspects such as packaging, labeling, placarding, and the training of transportation personnel. In China, the "Regulations on the Safety Management of Hazardous Chemicals" clearly define the safety management requirements for the transportation of highly toxic chemicals like Sodium cyanide. Exporters need to obtain export permits for controlled chemicals from national authorities before exporting, and an end - use certificate is required to obtain the export permit.

1.2 Permits and Licenses

Transportation companies must obtain specific permits and licenses to transport sodium cyanide. These permits are usually issued by relevant government departments after a comprehensive review of the company's safety management system, transportation equipment, and the qualifications of its employees. For example, in the transportation of dangerous goods in the European Union, companies need to comply with the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations and obtain the necessary ADR certificates.

2. Packaging and Labeling

2.1 Packaging Materials

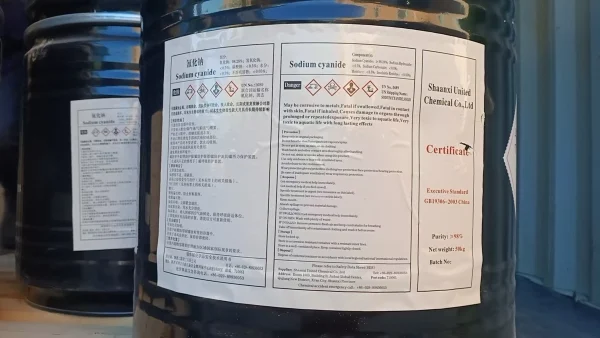

Solid Sodium Cyanide: Solid sodium cyanide is often transported in steel drums with a net weight of 50 kg. These drums are equipped with inner PE bags to prevent leakage. Plywood boxes with a net weight of 1000 kg, lined with inner PE and PP laminated woven bags, are also commonly used. The packaging materials must be corrosion - resistant and have sufficient strength to withstand normal handling and transportation shocks.

Sodium Cyanide Solution: Aqueous sodium cyanide is usually transported in "tight - fill" (closed - loop) systems. For rail transportation, it is loaded or unloaded into rail cars via chemical hoses or PTFE - lined loading arms. Tank trucks used for transporting sodium cyanide solution should meet the established DOT requirements, such as MC 307 or low - pressure chemical ISO containers. All trailers must be equipped with pressure relief valves, and those with bottom outlets must be equipped with remote - controlled stop valves.

2.2 Labeling and Placarding

Warning Labels: All packages containing sodium cyanide must be clearly labeled with warning labels. These labels should indicate the name of the chemical, its toxic nature, and the necessary hazard warnings, such as "Poison," "Toxic by Inhalation," and "Danger: Can Cause Death." The labels should be in a language that is easily understood in the transportation area.

Placards: Vehicles transporting sodium cyanide must display appropriate placards on all four sides. These placards are large, diamond - shaped signs that clearly identify the hazardous nature of the cargo. For sodium cyanide, the placard will typically show the UN number (UN1689 for solid sodium cyanide and UN3414 for sodium cyanide solution), the class (Class 6.1. representing toxic substances), and the appropriate hazard symbol.

3. Transportation Equipment and Conditions

3.1 Vehicle Requirements

Rail Transportation: Sodium cyanide is typically shipped in 26.000 - gallon DOT - 111 insulated or non - insulated tank cars with safety valves. The rail cars have an outside diameter of about 9 feet and an overall length of 45 - 55 feet, with a 6' x 6' center opening or offset crash box openings. The tank cars must be regularly inspected for any signs of corrosion, leakage, or damage.

Road Transportation: Tank trucks used for transporting sodium cyanide must meet strict safety standards. They should be equipped with safety devices such as emergency shut - off valves, pressure gauges, and anti - rollover protection. The vehicles should also have a reliable braking system and be well - maintained to ensure safe transportation on the road.

Air Transportation: When transporting sodium cyanide by air, special precautions are required. For example, in a case where 25.7 tons of cyanide needed to be transported from Xi'an to Mongolia, the carrier took multiple safety measures. The cargo was packed in a "sealed bag inner package + steel drum outer package" manner. The steel drums filled with sodium cyanide were firmly fixed on a pressure - bearing tray to prevent collision and movement during flight. Airlines usually assign experienced flight crews for such special cargo flights.

3.2 Environmental Conditions

Temperature and Humidity Control: Sodium cyanide should be transported in an environment that avoids high temperatures and humidity. High temperatures can increase the risk of chemical reactions, and humidity can cause the solid sodium cyanide to absorb moisture and potentially release toxic hydrogen cyanide gas. Vehicles and storage facilities should be equipped with appropriate temperature and humidity control devices if necessary.

Avoidance of Shock and Vibration: During transportation, the vehicle should avoid excessive shock and vibration. Rough driving, such as frequent sudden braking and sharp turns, can cause the packages to collide and potentially damage the packaging, leading to leakage. Therefore, drivers should be trained to drive smoothly and avoid such situations.

4. Personnel Training and Safety Measures

4.1 Training Requirements

General Awareness Training: All personnel involved in the transportation of sodium cyanide, including drivers, loaders, and supervisors, must receive general awareness training on hazardous materials. This training includes knowledge of the properties of sodium cyanide, the potential hazards it poses, and the basic safety procedures to follow.

Function - Specific Training: Personnel should also receive function - specific training related to their job responsibilities. For example, drivers need to know how to respond to emergency situations during transportation, such as a spill or a vehicle accident. Loaders should be trained on proper loading and unloading procedures to ensure the safety of the cargo and themselves.

Recurrent Training: Regular recurrent training is necessary to keep the knowledge and skills of the personnel up - to - date. This helps to ensure that they are always aware of the latest safety regulations and best practices in the transportation of sodium cyanide.

4.2 Safety Measures

Personal Protective Equipment (PPE): When handling sodium cyanide, all personnel must wear appropriate PPE. This includes rubber gloves, aprons, boots, goggles, and dust - proof or gas masks. PPE helps to prevent direct contact with the chemical and inhalation of its toxic fumes.

Ventilation: Loading and unloading areas, as well as the interior of transportation vehicles, should be well - ventilated. Good ventilation can reduce the concentration of toxic gases in the air and minimize the risk of inhalation by personnel. In areas where sodium cyanide is handled for a long time, mechanical ventilation equipment should be installed.

Emergency Response Plans: Transportation companies must have detailed emergency response plans in place. These plans should outline the procedures to be followed in case of a spill, leakage, or other emergencies. The plans should include contact information for relevant emergency response agencies, such as local fire departments, environmental protection agencies, and poison control centers.

5. Emergency Response and Spill Management

5.1 Emergency Response Plan

Pre - planned Procedures: In the event of an accident or spill involving sodium cyanide, a pre - planned emergency response plan must be activated immediately. The plan should detail the steps to be taken to protect human life, prevent the spread of the spill, and minimize environmental damage. For example, it should specify how to evacuate the surrounding area, how to contain the spill, and how to neutralize the sodium cyanide.

Communication: Clear and effective communication is crucial during an emergency. The transportation company should immediately notify local emergency response agencies, as well as the relevant regulatory authorities. In addition, communication channels should be established with the surrounding communities to inform them of the situation and any necessary evacuation or safety measures.

5.2 Spill Management

Containment: When a spill occurs, the first step is to contain the sodium cyanide to prevent its spread. This can be done using absorbent materials, such as sand or special spill - control booms. The area around the spill should be cordoned off to prevent unauthorized access.

Neutralization: Liquid hydrogen cyanide (produced when sodium cyanide reacts with water) and any remaining sodium cyanide should be neutralized. For this purpose, strong oxidizing agents like hydrogen peroxide or sodium thiosulfate can be used. The neutralization process should be carried out by trained professionals following strict safety procedures.

Clean - up and Disposal: After neutralization, the contaminated materials, including the absorbent materials and any soil or water affected by the spill, must be properly cleaned up and disposed of. This usually involves transporting the materials to a licensed hazardous waste disposal facility for safe treatment.

In conclusion, the transportation of sodium cyanide is a highly regulated and safety - critical operation. By strictly complying with all the requirements related to Regulatory Compliance, packaging, transportation equipment, personnel training, and emergency response, the risks associated with transporting this highly toxic chemical can be effectively minimized, ensuring the safety of people and the environment.

- Random Content

- Hot content

- Hot review content

- Flexible Customer and Supplier Relations Specialist (Location: India)

- Industrial Grade Sodium Metabisulfite 96.5%

- Sodium Amyl Xanthate (SAX) 90%, Mining chemical, mining flotation reagent

- High-precision Delay Element( 25ms- 10000ms)

- industry Electric Detonator

- Cyanoacetic acid 99% Powder

- Antimonium Tartrate Potassium

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: