Sodium cyanide is a crucial component in the Gold mining industry, particularly as a Leaching agent. Below are five frequently asked questions that will help you better understand the role of Sodium cyanide in mining.

1. What is Sodium Cyanide, and how is it used in gold mining?

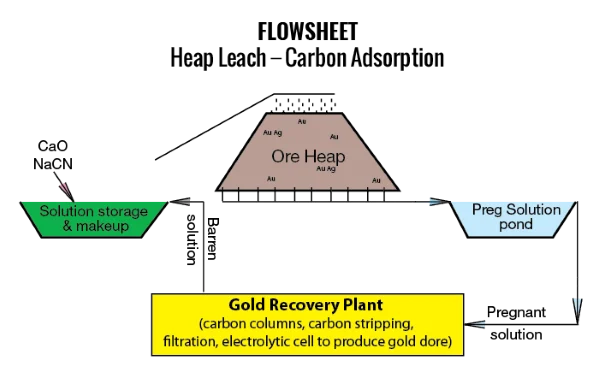

Sodium cyanide is a highly toxic chemical compound that is primarily used in the gold Mining industry for the extraction of gold from ore. It works by forming a complex with gold, allowing it to be separated from other materials in the ore through a process known as cyanidation. This method is effective for extracting gold from low-grade ores.

2. Why is sodium cyanide preferred over other leaching agents?

Sodium cyanide is preferred due to its high efficiency in dissolving gold and its ability to work effectively in a variety of conditions. It has a relatively low cost compared to other leaching agents and can extract gold from ores that contain very low concentrations of the metal. Additionally, the process can be easily controlled and monitored, making it a popular choice in the industry.

3. What are the environmental concerns associated with sodium cyanide?

The use of sodium cyanide in gold mining raises significant environmental concerns due to its toxicity. If not managed properly, cyanide can contaminate water sources, harm aquatic life, and pose health risks to nearby communities. Mining companies are required to implement strict safety measures and waste management practices to minimize the risk of cyanide spills and leaks.

4. How do mining companies ensure the safe use of sodium cyanide?

Mining companies implement a variety of safety protocols to ensure the safe use of sodium cyanide. These include training workers on handling and emergency response, using closed-loop systems to minimize exposure, regular monitoring of cyanide levels in the environment, and adhering to regulatory guidelines. Additionally, many companies are investing in research to develop alternative methods for Gold extraction that are less harmful to the environment.

5. Are there any alternatives to sodium cyanide in gold mining?

Yes, several alternatives to sodium cyanide are being researched and developed, including thiosulfates and Eco-Gold Leaching Chemicals. These alternatives aim to reduce the environmental impact and toxicity associated with traditional cyanide leaching. However, many of these methods are still in the experimental stages and may not yet be as effective or cost-efficient as sodium cyanide for large-scale gold extraction.

By understanding these key aspects of sodium cyanide, you can gain a better insight into its role in gold mining and the associated challenges and responsibilities.

- Random Content

- Hot content

- Hot review content

- Caustic soda Flakes NaOH 96%-99% Sodium hydroxide

- Polyethylene Glycol PEG - 2000/4000/6000/8000 alcohol ethoxylate surfactant

- Ammonium Chloride 99.5% Mining Collector

- Sodiumsulfite Technical Grade 96%-98%

- Manganese sulfate

- Phthalic anhydride

- 97% 2-Hydroxypropyl methacrylate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 5Anhydrous Oxalic acid 99.6% Industrial Grade

- 6Oxalic acid for mining 99.6%

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: