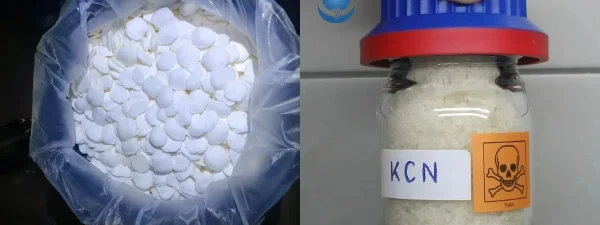

In the gold mining industry, cyanide leaching remains one of the most widely used methods for extracting gold from ore. Sodium cyanide, in particular, is favored for its effectiveness, stability, and relatively low cost. Determining the optimal sodium cyanide concentration is crucial as it directly impacts the efficiency of gold extraction, operational costs, and environmental considerations.

Theoretical Considerations

Theoretically, the dissolution of gold in a cyanide solution follows a specific chemical reaction. For every gram of gold to be dissolved, approximately 0.92 grams of Sodium Cyanide are required based on electrochemical reactions. However, in real - world scenarios, the actual consumption of Sodium cyanide is significantly higher, often 50 - 100 times the theoretical amount.

Factors Affecting Optimal Concentration

Ore Characteristics

Gold Mineralogy: The type of gold minerals present in the ore plays a vital role. If the gold is in a fine - grained, free - milling form, it will require a different cyanide concentration compared to gold that is associated with sulfide minerals or other refractory materials. For example, in some gold - bearing quartz veins, where the gold is relatively free - milling, lower cyanide concentrations may be sufficient.

Particle Size and Permeability: Finer - grained ores generally have a higher surface area, which allows for more efficient contact between the sodium cyanide solution and the gold particles. As a result, a lower cyanide concentration might be effective. In contrast, coarser - grained ores may need a higher concentration to ensure complete leaching. Additionally, the permeability of the ore particles affects the flow of the cyanide solution through the ore, influencing the required concentration.

Presence of Other Metals: Copper, in particular, reacts strongly with sodium cyanide. It can consume a significant amount of cyanide during the leaching process. For every gram of copper dissolved, 2.3 to 3.4 grams of cyanide are typically required. In ores with high copper content, a higher sodium cyanide concentration may be necessary to ensure that there is enough cyanide available for gold dissolution. Other metals such as zinc, lead, and iron can also impact the cyanide consumption, albeit to a lesser extent.

Process Conditions

pH Level: The pH of the leaching solution is a critical factor. Sodium cyanide hydrolyzes in solution, producing hydrocyanic acid (HCN), which is a highly toxic gas. The degree of hydrolysis depends on the pH of the solution. At a pH of 10.5. only 6.1% hydrocyanic acid is produced, while at a pH of 9.0. 67.1% is produced. To minimize cyanide loss through hydrolysis and to ensure the stability of the cyanide solution, the pH is usually maintained between 11 and 12 in gold CIP (Carbon - in - Pulp) plants. This also has an impact on the optimal sodium cyanide concentration, as a more alkaline environment may require a slightly higher concentration for effective gold leaching.

Dissolved Oxygen Concentration: Oxygen is essential for the dissolution of gold in a cyanide solution. The reaction requires both cyanide ions (CN⁻) and oxygen (O₂). The maximum solubility of oxygen at room temperature and pressure is 8.2 mg/L. If the dissolved oxygen concentration in the slurry is less than 4 mg/L, it can limit the gold dissolution rate. In such cases, air can be injected into the slurry or hydrogen peroxide can be added to increase the oxygen concentration. The ratio of oxygen to cyanide is crucial; an imbalance can lead to a decrease in the leaching rate. As the oxygen concentration affects the reaction kinetics, it also influences the optimal sodium cyanide concentration. A higher oxygen concentration may allow for a slightly lower cyanide concentration, and vice versa.

Typical Concentration Ranges in Practice

In CIP and CIL (Carbon - in - Leach) Processes: In a typical CIP or CIL circuit, where the gold - bearing ore is in a slurry form and carbon is used to adsorb the dissolved gold, the sodium cyanide concentration is generally maintained in the range of 0.3 - 0.4 grams per liter (0.03 - 0.04%). This concentration range has been found to be effective for a wide range of ore types under normal operating conditions. However, for more complex ores or those with high impurity levels, the concentration may be adjusted upwards, sometimes reaching up to 0.6 - 0.8 grams per liter (0.06 - 0.08%).

In Vat Leaching: Vat leaching is often used for coarser - grained ores or when the ore is processed in batches. In this process, the sodium cyanide concentration is typically higher, around 1.0 gram per liter (0.1%). The higher concentration compensates for the potentially lower surface area of the coarser ore particles and helps to ensure that the cyanide solution can penetrate the ore and dissolve the gold effectively.

For Tailings Cyanidation: When cyaniding the tailings from previous processing steps (such as after gravity separation), the cyanide concentration may vary depending on the remaining gold content and the nature of the tailings. Generally, the cyanide concentration can range from 0.5 - 2 kg/t of ore, which, when converted to a solution concentration, can be in the range of 0.05 - 0.2 grams per liter (0.005 - 0.02%). The lower concentration is often sufficient as the tailings may have already been pre - treated, and the remaining gold is more accessible.

Environmental and Safety Implications

While determining the optimal sodium cyanide concentration for gold leaching, it is essential to consider environmental and safety aspects. Cyanide is a highly toxic substance, and any release into the environment can have severe consequences. Maintaining the proper concentration not only helps in efficient gold extraction but also minimizes the amount of cyanide that may be present in waste streams. Additionally, proper handling and storage of sodium cyanide are crucial to prevent accidental spills or releases.

Conclusion

The optimal sodium cyanide concentration range for gold leaching varies depending on multiple factors, including ore characteristics and process conditions. In general, for most common gold - leaching operations such as CIP, CIL, and vat leaching, the concentration ranges from 0.03% - 0.1% (0.3 - 1.0 grams per liter). However, for each specific ore body, it is recommended to conduct detailed laboratory tests, such as bottle roll and column tests, to accurately determine the most suitable sodium cyanide concentration. This will ensure maximum gold recovery while minimizing costs and environmental impacts.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- Sodium Isopropyl Xanthate 90% SIPX

- Dithiophosphate 25S

- High-precision Delay Element( 25ms- 10000ms)

- Isobutyl vinyl ether 98% high purity certified Professional producer

- Pharmaceutical Intermediate Glycine with High Quality 99%

- Di(ethylene Glycol) Vinyl Ether

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Oxalic acid for mining 99.6%

- 6Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: