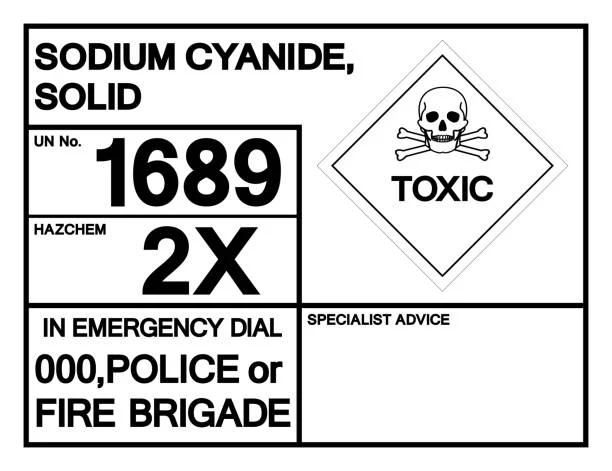

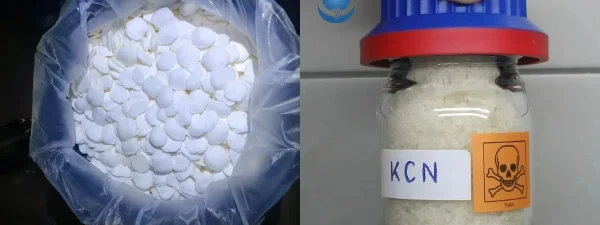

Sodium cyanide is a highly toxic chemical widely used in various industrial processes such as gold mining, electroplating, and chemical manufacturing. Due to its extreme toxicity and potential risks to human health and the environment, its use in factories is strictly regulated. Factories need to complete a series of documentation procedures to ensure legal and safe use. This article will provide a detailed introduction to the necessary documentation for factories using sodium cyanide.

1. Business License and Related Qualification Certificates

Business License: The factory must have a valid business license issued by the relevant administrative department for industry and commerce. This certificate serves as the legal basis for the factory's business activities, demonstrating its legitimate existence and business scope.

Industrial and Commercial Registration Information: It is necessary to ensure that the business scope in the industrial and commercial registration clearly includes the use of Sodium Cyanide - related business activities. If the original business scope does not cover this, an application for a change of business scope should be submitted in a timely manner.

2. Hazardous Chemicals - Related Permits

Hazardous Chemicals Use License: Apply to the local safety supervision department. To obtain this license, the factory needs to meet a series of safety requirements, including:

Having appropriate storage facilities for Sodium cyanide, which should be equipped with anti - leakage, anti - corrosion, and ventilation devices. For example, the storage area should be made of materials resistant to cyanide corrosion, and a double - layer containment system may be required to prevent leakage.

Establishing sound safety management systems, such as formulating operating procedures for the use of sodium cyanide, emergency response plans for potential cyanide leakage or other accidents, and employee safety training programs.

The factory's safety facilities and equipment should meet national standards, such as installing gas detectors for cyanide in relevant areas to monitor air quality in real - time.

Hazardous Chemicals Business License (if applicable): If the factory not only uses but also engages in the trading of sodium cyanide, it must obtain a hazardous chemicals business license. The application process for this license is more complex, requiring additional demonstration of the factory's trading capabilities, warehousing conditions for trading volume, and compliance with relevant trading regulations.

3. Environmental Protection - Related Documentation

Environmental Impact Assessment Report: For factories using sodium cyanide, an environmental impact assessment report needs to be prepared. This report should comprehensively evaluate the potential environmental impacts of the factory's use of sodium cyanide, including:

The impact of cyanide - containing wastewater discharge on surface water and groundwater. The report should propose appropriate wastewater treatment measures, such as the use of chemical precipitation methods to remove cyanide from wastewater before discharge.

The impact of cyanide - containing waste gas emissions on the atmosphere. If there is a possibility of cyanide - containing gas generation during the production process, measures such as installing gas purification devices should be proposed.

The management and disposal of cyanide - containing solid waste. Cyanide - containing solid waste should be classified as hazardous waste and must be disposed of by qualified units.

Pollution Discharge Permit: After obtaining the approval of the environmental impact assessment report, the factory should apply for a pollution discharge permit from the local environmental protection department. This permit clearly stipulates the types, quantities, and discharge standards of pollutants (including cyanide - related pollutants) that the factory is allowed to discharge.

4. Safety and Security - Related Documentation

Safety Evaluation Report: Commission a qualified safety evaluation agency to conduct a safety evaluation of the factory's sodium cyanide - using project. The evaluation report should cover all aspects of safety, such as:

Evaluation of the safety of the production process, including whether the use of sodium cyanide in the production line is in line with safety standards, and whether there are potential safety hazards in the transportation and transfer of sodium cyanide within the factory.

Evaluation of the safety of storage facilities, including the design, construction, and operation of storage tanks and warehouses for sodium cyanide.

Evaluation of the effectiveness of safety management systems, such as whether the emergency response plan can be effectively implemented in case of an accident.

Security Measures and Documentation: Since sodium cyanide is a highly toxic and potentially dangerous chemical, the factory needs to implement strict security measures and document them. This includes:

Installing security monitoring systems in the storage and use areas of sodium cyanide to ensure 24 - hour surveillance.

Establishing a personnel access control system, only allowing authorized personnel to enter the relevant areas. Employee background checks may also be required to ensure the safety of the operation of sodium cyanide.

Documenting security management systems, such as security patrol records, access records, etc.

5. Transportation - Related Documentation (if applicable)

Hazardous Chemicals Transportation Permit: If the factory is responsible for the transportation of sodium cyanide, it must obtain a hazardous chemicals transportation permit. To obtain this permit, the following conditions need to be met:

The transportation vehicles should meet the safety standards for transporting hazardous chemicals, such as being equipped with anti - spill, fire - prevention, and explosion - proof devices.

The drivers and escorts of the transportation vehicles should have the corresponding qualifications and certificates for transporting hazardous chemicals, and have received relevant safety training.

Transportation Contract and Insurance Documentation: When entrusting a third - party transportation company to transport sodium cyanide, the factory should sign a formal transportation contract. In addition, it is necessary to ensure that the transportation company has purchased appropriate insurance to cover potential risks during transportation, such as cargo insurance for hazardous chemicals.

6. Other Regulatory - Compliance Documentation

Compliance with International and Domestic Chemical Control Regulations: Sodium cyanide may be subject to international chemical control regulations such as those of the Organization for the Prohibition of Chemical Weapons. Factories need to ensure compliance with these regulations and may need to provide relevant documentation to prove compliance, such as declarations of non - use for chemical weapons - related purposes.

Record - Keeping and Reporting Requirements: Factories are often required to keep detailed records of the purchase, use, storage, and disposal of sodium cyanide. Regular reports may also need to be submitted to relevant government departments, such as the safety supervision department and the environmental protection department, to facilitate regulatory monitoring.

In conclusion, factories using sodium cyanide need to complete a series of complex documentation procedures to ensure legal operation, safety, and environmental protection. Complying with these requirements is not only a legal obligation but also crucial for protecting the safety of employees, the public, and the environment.

- Random Content

- Hot content

- Hot review content

- Toxicity Assessment of Sodium Cyanide and Relevant Hazard Prevention Measures

- Caustic soda Flakes NaOH 96%-99% Sodium hydroxide

- Shock Tube Detonator

- Cyanoacetic acid 99% Powder

- Feed Grade 98.0% Calcium Formate

- Fertilizer magnesium sulfate/magnesium sulfate monohydrate

- Phosphoric Acid 85% (Food grade)

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Anhydrous Oxalic acid 99.6% Industrial Grade

- 5Oxalic acid for mining 99.6%

- 6Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 7Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: